Description

Why Water Spray Testing Matters

Water ingress testing ensures that sealed components perform reliably in environments where moisture, rain, and water jets are present. Failure to test can result in product malfunctions, safety issues, and costly warranty claims. The IPX1 to IPX4 water mist chamber series allows manufacturers to validate their products against different water exposure conditions:- IPX1 – Protection against vertically falling water drops (drip tests).

- IPX2 – Protection against dripping water when tilted at up to 15°.

- IPX3 – Protection against spraying water up to 60° from vertical.

- IPX4 – Protection against splashing water from any direction.

Key Features of Testron Water Spray Chambers

Every water spray chamber in the USA designed by Testron is manufactured to meet strict international standards. Our models include multiple performance-driven features:- Comprehensive Testing – Perform IPX1, IPX2, IPX3, and IPX4 tests in a single chamber.

- Durable Construction – Built with SUS304 stainless steel interiors for corrosion and rust resistance.

- Precision Water Control – Adjustable oscillating tube and spray nozzles for accurate water distribution.

- Efficient Water Recirculation System – Reduces water consumption, making testing cost-efficient.

- Rotating Turntable – Ensures uniform exposure across test specimens.

- User-Friendly Interface – Programmable color LCD touch-screen controller with USB and Ethernet.

- Built-in Safety Protection – Includes over-current, water shortage, and over-temperature safeguards.

- Certified Quality – CE mark and ISO17025 calibration provided.

Available Models and Specifications

Testron offers different models of water spray test chambers to meet the varying needs of manufacturers.- R-800

- Internal Dimensions: 900×950×950 mm

- Overall Dimensions: 1130×1400×1870 mm

- Oscillating Tube Radius: 400 mm

- Swing Angle: 0° to ±180° Adjustable

- R-1200

- Internal Dimensions: 1300×1350×1400 mm

- Overall Dimensions: 1550×1830×2220 mm

- Oscillating Tube Radius: 1600 mm

- Swing Angle: 0° to ±180° Adjustable

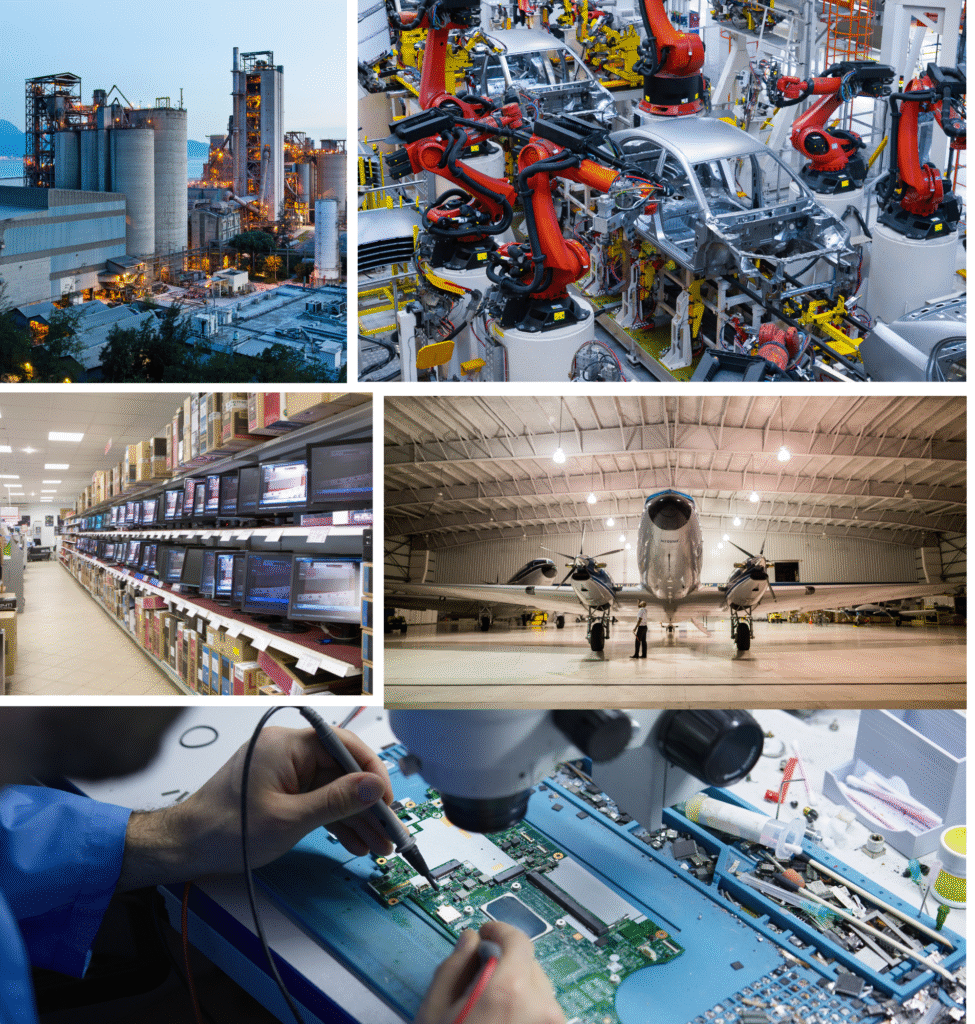

Applications Across U.S. Industries

Our water spray environmental chambers are widely used across industries in the United States:- Automotive – Testing headlamps, rear lamps, mirrors, and sensor housings.

- Electronics – Verifying waterproof performance of connectors, switches, and circuit boards

- Consumer Products – Ensuring reliability of household appliances and wearable devices.

- Defense and Aerospace – Evaluating ruggedized equipment and communication systems.

- Industrial Equipment – Certifying enclosures, control units, and junction boxes.

Cost Considerations: Water Spray Chamber Price in the USA

One of the key questions for buyers is the water spray chamber price. The cost depends on several factors:- Chamber Size and Capacity – Larger chambers (up to 2700 liters) cost more than smaller models.

- Testing Capabilities – Chambers with multiple oscillating tubes and handheld nozzles add value.

- Automation & Control – Programmable systems with Ethernet and USB increase efficiency but also price.

- Customization – Tailored designs for specific industries may affect the investment.

Why Choose Testron as Your Water Spray Chamber Manufacturer in the USA?

Testron is a leading water spray chamber supplier trusted by U.S. manufacturers for:

- Compliance with Global Standards – IEC 60529, ISO17025, and CE certifications.

- Customization Options – From compact water mist chambers to large-volume chambers.

- After-Sales Support – U.S.-based service and calibration support.

- Durability – Chambers built with long-lasting stainless steel interiors.

- Value for Money – Competitive water spray chamber price for advanced features.

- Innovation – Integrated with smart water spray systems for energy and water efficiency.

This makes Testron a preferred water spray chamber manufacturer in the USA for both small and large industries.

How to Select the Right Water Spray Chamber

When choosing a water spray environmental chamber, U.S. companies should consider:- Testing requirements (IPX1 to IPX4)

- Chamber size and capacity (729L vs 2700L)

- Type of products being tested (electronics vs automotive assemblies)

- Budget and long-term ROI (based on water spray chamber price)

- Supplier’s after-sales service and calibration support

Frequently Asked Questions

What is the purpose of a water spray chamber in the USA?

It is used to test the water ingress resistance of products, ensuring compliance with IPX1–IPX4 standards.

What is the typical water spray chamber price range?

Costs vary depending on capacity and features. Smaller water mist chambers are more affordable, while larger, fully automated systems are higher priced.

Who needs a water spray environmental chamber?

Industries like automotive, electronics, defense, and consumer goods manufacturers use them for compliance and reliability testing.

Can Testron customize a water spray chamber?

Yes, we provide custom-built chambers tailored to client-specific requirements in the USA.

What is the difference between a water spray system and a water mist chamber?

A water spray system uses oscillating tubes and nozzles for controlled sprays, while a water mist chamber simulates fine mist or light rain conditions.

Why choose Testron as a water spray chamber supplier in the USA?

Because of our proven quality, competitive pricing, U.S. service support, and compliance with global standards.