Description

Why Choose an IPX5 IPX6 Water Jetting Test Chamber in the USA?

Water resistance testing is a regulatory requirement. The IPX5 and IPX6 waterproof tests ensure enclosures withstand powerful water jets. Utilizing a professional IP test chamber ensures your product simulations are accurate to real-world exposure.

- IPX5 Test– Water projected by a 6.3mm nozzle at a flow rate of 12.5 L/min from all directions.

- IPX6 Test– Water projected by a 12.5mm nozzle at a flow rate of 100 L/min at high pressure.

A combined IPX5 IPX6 water jetting test chamber in the USA allows both tests in one unit, making it a cost effective and efficient solution for R&D labs, quality control departments, and third party testing laboratories. As a top water jetting test chamber supplier, we ensure our water jet testing equipment meets the highest industry standards.

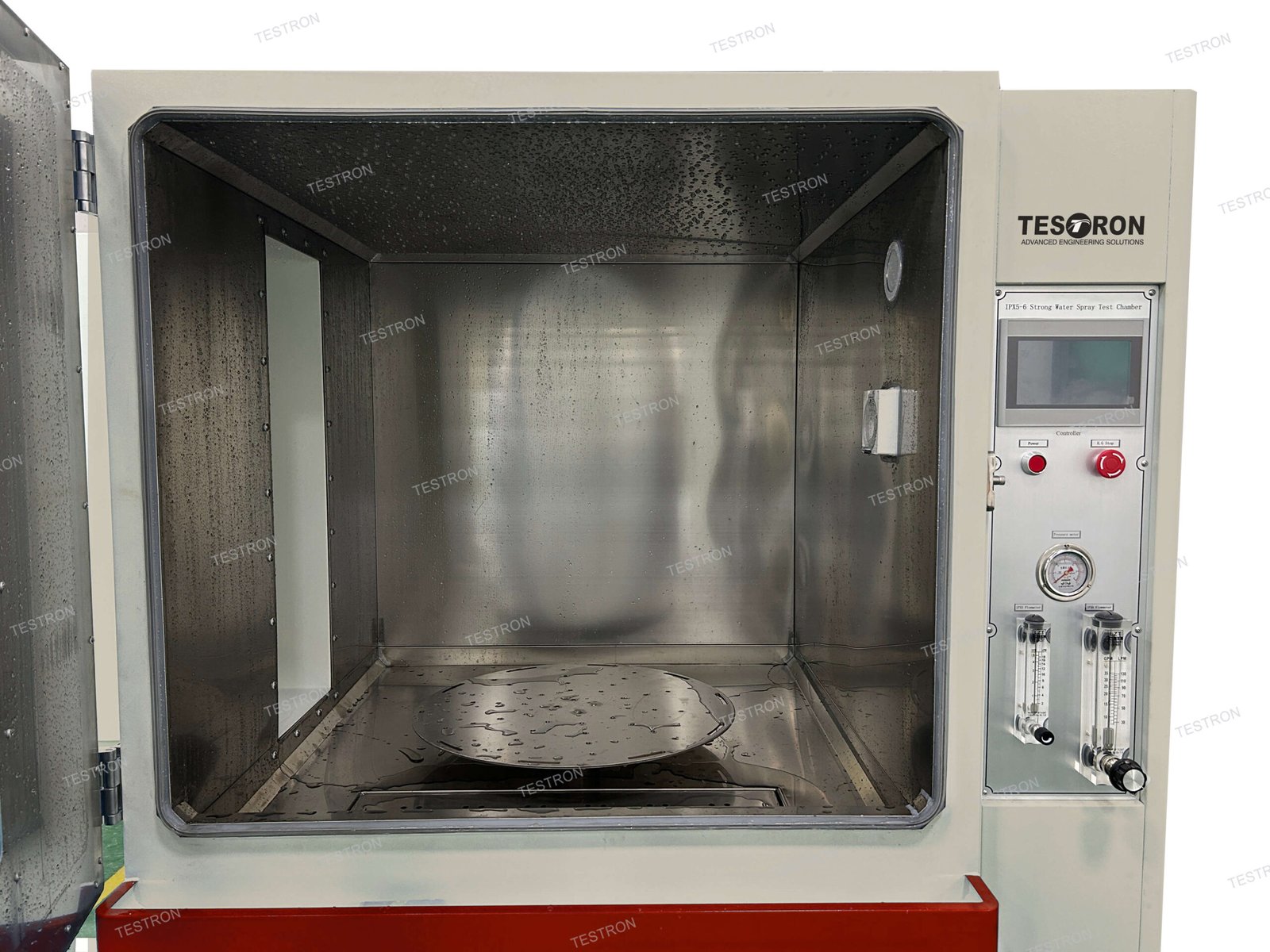

Features of Testron’s IPX5 IPX6 Water Jetting Test Chamber

Our water jet testing equipment is designed with cutting edge features that ensure accuracy, repeatability, and ease of use. Whether you need an environmental chamber for small components or large industrial gear, our range covers it all.

- Dual Functionality– Perform both IPX5 and IPX6 tests in one chamber

- Customizable Capacities– Available in 800L, 1000L, 1500L, and 2000L models with options for customization

- Flow Rate Control– Adjustable water flow rates (12.5 L/min for IPX5, 100 L/min for IPX6) with precise monitoring

- Programmable Controller– Touchscreen display with USB & Ethernet for data storage and remote monitoring

- Viewing Window & Illumination– Real-time visual inspection with internal LED lighting and wiper system

- Waterproof Power Connectors– Allows safe testing of powered specimens

- Automatic Water Supply & Safety System– Ensures uninterrupted operation with built-in over-pressure and leak protection

- Compliance & Certification– Conforms to IEC 60529, CE Marking, and ISO 17025 calibration standards

Technical Specifications of our Water Jetting Test Chamber in the USA

| Feature | IPX5 | IPX6 |

|---|---|---|

| Flow Rate | 12.5 L/min ±5% | 100 L/min ±5% |

| Nozzle Diameter | 6.3 mm | 12.5 mm |

| Water Pressure | 30 kPa | 100 kPa |

| Test Duration | 1–3 min per surface | 1–3 min per surface |

| Rotation | 0–360° Adjustable | 0–360° Adjustable |

| Chamber Sizes | 800L, 1000L, 1500L, 2000L | Custom sizes available |

| Controller | Color touchscreen | USB & Ethernet data storage |

Available Models of Water Jetting Test Chamber

| Model | Internal Dimensions (mm) | Overall Dimensions (mm) | Capacity | Temp. Range |

|---|---|---|---|---|

| DI-800 | 800 × 1000 × 1000 | 1040 × 1450 × 1960 | 800 L | Ambient to +50°C |

| DI-1000 | 1000 × 1000 × 1000 | 1200 × 1450 × 1960 | 1000 L | Ambient to +50°C |

| DI-1500 | 1000 × 1500 × 1000 | 1250 × 1900 × 1960 | 1500 L | Ambient to +50°C |

| DI-2000 | 1000 × 2000 × 1000 | 1300 × 2400 × 1960 | 2000 L | Ambient to +50°C |

Each water jetting testing chamber can be custom built to match industry specific needs, making Testron one of the most trusted water jetting test chamber manufacturers and suppliers in the USA.

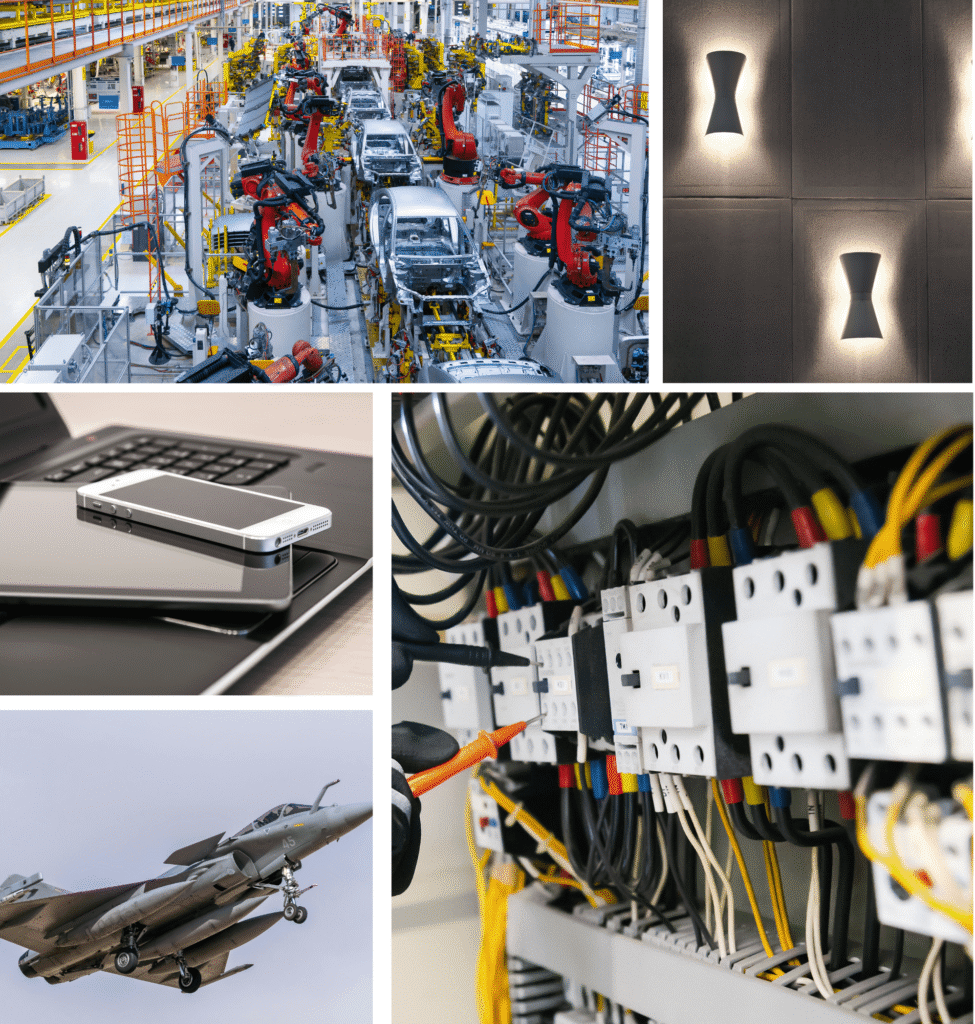

Applications of Water Jetting Test Chambers

The IPX5 & IPX6 water jet testing equipment is widely used across industries for IP waterproof testing.

- Automotive Industry

Testing headlights, taillights, sensors, wiring harnesses, and power connectors.

Ensures vehicle components survive heavy rain and road spray conditions. - Consumer Electronics

Used for smartphones, tablets, speakers, and wearables.

Validates marketing claims such as “water resistant up to IPX6”. - Outdoor Lighting & Smart Poles

Ensures streetlights, floodlights, and solar lights resist heavy jetting water exposure. - Defense & Aerospace

Tests equipment used in harsh weather and marine environments. - Electrical Enclosures

Switchboards, junction boxes, and control panels are tested for water ingress protection.

High Quality Water Jet Testing Equipment by Testron

Apart from the IPX5 & IPX6 Water Jetting Test Chamber in the USA, Testron also provides advanced IP test equipment from expert water jet testing equipment manufacturers:

- Rain Test Chambers (IPX1–IPX4) for dripping and spraying water.

- Dust Test Chambers (IP5X, IP6X) for ingress protection against fine particles.

- Immersion Test Tanks (IPX7, IPX8) for submersion resistance testing.

By combining these systems, manufacturers can achieve complete IP protection testing (IPX1-IPX8) under one roof.

Water Jetting Test Chamber Price

The water jetting test chamber price varies depending on:-

- Capacity (800L – 2000L)

- Customization level (automation, data logging, safety features)

- Location (USA, Europe, Asia)

- Supplier & Warranty

Testron offers a competitive water jetting test chamber price with full after sales support, calibration services, and spare parts availability. To get an exact water jetting test chamber price in the USA, contact our sales team for a tailored quote.

Why Testron Group is a Leading Water Jetting Test Chamber Supplier

- Global Reach: Offices in China, UAE, and USA to support international clients.

- Customization: Tailored chambers to meet unique industry specifications.

- Certifications: CE, ISO 17025 calibration, and IEC compliance.

- After Sales Support: Training, calibration, and spare part availability.

- Trusted by Industry Leaders: Automotive OEMs, electronics giants, and certified labs rely on Testron.

How to Select the Right Water Jet Test Machine

When choosing a water jetting test chamber, consider:

- Specimen Size: Ensure chamber capacity fits your largest product.

- Required IP Rating: If higher IPX7/8 needed, opt for multi-purpose IP chambers.

- Automation & Data Needs: Advanced models provide USB/Ethernet connectivity for reports.

- Budget & Price Range: Match features to your testing requirements and budget.

Compliance & Certifications

Testron’s chambers are designed and certified to meet:

- IEC 60529 (International Protection Marking Standard)

- ISO/IEC 17025 Calibration

- CE Safety Certification

- RoHS & Environmental Standards

FAQs : IPX5 & IPX6 Water Jetting Test Chamber

What is the difference between IPX5 and IPX6 testing?

IPX5 uses 12.5 L/min spray from a 6.3 mm nozzle, while IPX6 uses 100 L/min high pressure jet from a 12.5 mm nozzle.

What industries require IPX5/IPX6 testing?

Automotive, electronics, outdoor lighting, aerospace, defense, and consumer products.

What is the price of a water jetting test chamber in the USA?

The price depends on size, customization, and features. Contact Testron for a tailored quotation.

Can I perform IPX7/IPX8 tests in the same chamber?

No, IPX7/8 require immersion test tanks. Testron provides separate equipment for complete IP testing.

Why choose Testron as a water jet testing equipment supplier?

Because of high quality manufacturing, international certifications, competitive price, and global support.

Conclusion

The IPX5 IPX6 Water Jetting Test Chamber in the USA is an essential piece of environmental testing equipment for verifying waterproof performance. Testron Group, a leading water jetting test chamber supplier and water jetting test chamber manufacturer, provides state of the art water jet testers trusted by industries worldwide.

Whether you are looking for a water jetting test chamber in the USA, need a competitive water jetting test chamber price quote, or require a customized water jet test machine, Testron ensures precision, compliance, and reliability in every machine.

Contact us today to request a quotation and technical consultation for your water jetting testing chamber needs.