Description

Why Sand and Dust Testing is Important

Dust and sand particles may seem harmless, but in electronics, automotive, and aerospace systems, they can cause critical failures, which is why the Testron Group emphasizes rigorous testing. Fine dust can clog vents, damage electrical circuits, and reduce cooling efficiency. Sand exposure, on the other hand, can scratch surfaces, degrade seals, and affect mechanical performance.

Sand and dust chambers help simulate:

- Ingress testing : Evaluating how well seals and enclosures resist dust intrusion.

- Durability validation : Ensuring materials withstand abrasion caused by sand particles.

- Performance stability : Confirming product reliability when exposed to dusty outdoor conditions.

- Regulatory compliance : Meeting industry standards like MIL-STD-810G and IEC60529 (IP5X and IP6X ratings).

By using a larger sand and dust test chamber in the USA, companies achieve higher accuracy in their environmental chamber protocols, saving time and reducing long-term costs.

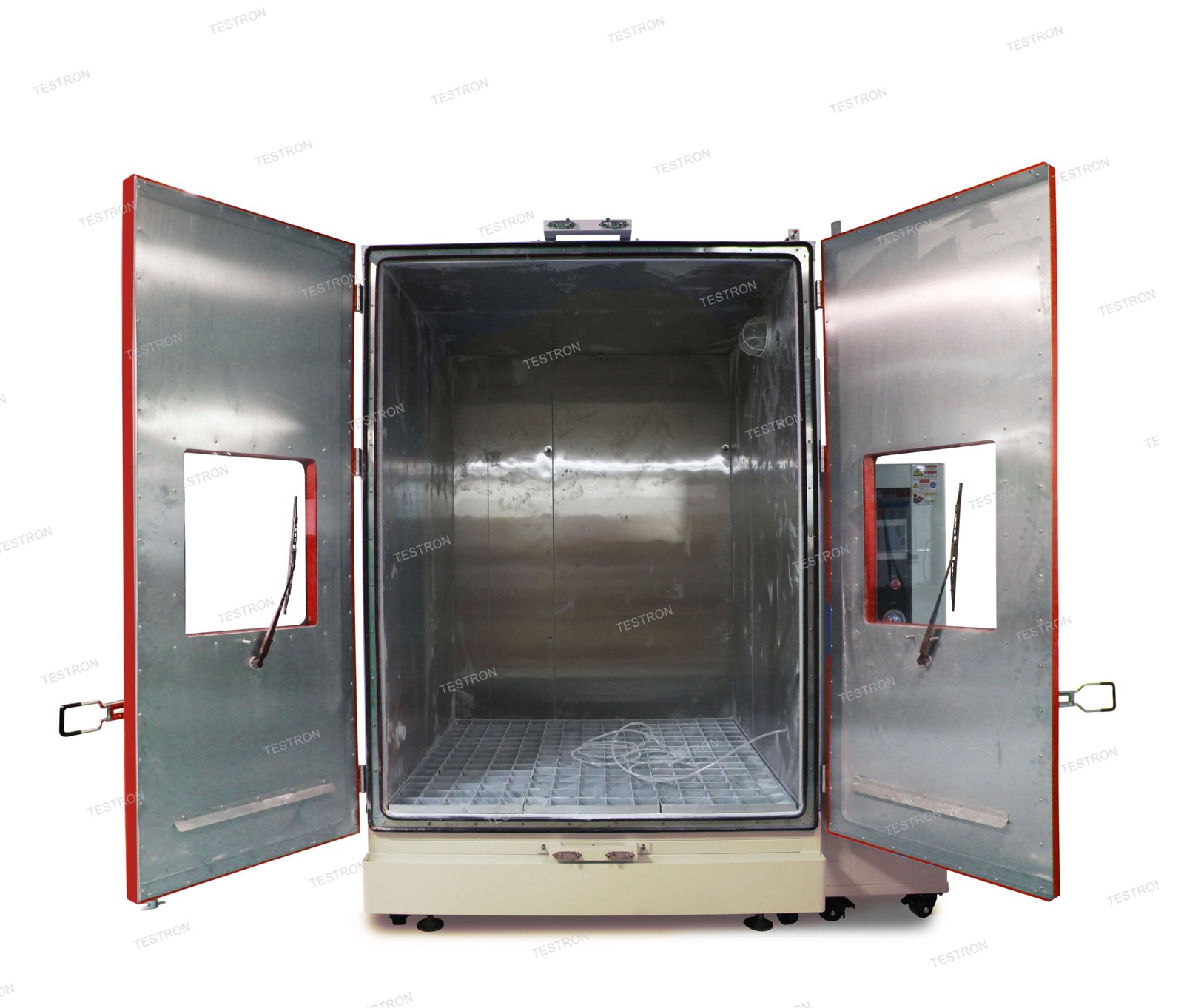

Key Features of Testron’s Larger Sand and Dust Test Chambers

Our systems are engineered with advanced technology to meet USA industry needs. Below are the standout features of our environmental test chamber models:

- Large capacity models: 1500 liters and 2000 liters

- Suitable for testing larger specimens or multiple products simultaneously

- Special wind tunnel system for consistent dust blowing

- Maintains constant dust concentration for accuracy

- Dual viewing windows with wipers for easy observation

- Dual doors with tight sealing to prevent leakage

- Programmable color LCD touchscreen controller

- Multi language operation interface

- USB and Ethernet connectivity for data storage and remote monitoring

- Stainless steel shelves for strength and durability

- Built in power interface and vacuum system for specimens

- Internal illumination for better visibility during tests

- CE Mark and ISO17025 calibration compliance

Models Available for the Larger Sand and Dust Test Chamber in the USA

| Model | Internal Dimensions (mm) | Overall Dimensions (mm) | Temperature Range | Talcum Powder Amount |

|---|---|---|---|---|

| DI-1500 | 1000 × 1500 × 1000 | 1250 × 1900 × 1960 | Ambient to +50℃ | 2 ~ 4 kg/m³ |

| DI-2000 | 1000 × 2000 × 1000 | 1300 × 2400 × 1960 | Ambient to +50℃ | 2 ~ 4 kg/m³ |

These larger models provide the flexibility and volume required for industrial scale dust testing.

Applications of Larger Sand and Dust Test Chambers in the USA

The larger sand and dust test chamber in the USA has become an essential testing solution across multiple industries. These chambers are specifically designed for sectors where product reliability under extreme dusty environments determines long-term safety and performance.

- Automotive Industry : Testing headlights, brake assemblies, air filters, electronic sensors, and engine components against dust ingress. Automotive OEMs in the USA depend on these chambers to meet ISO20653 and SAE standards before market launch.

- Defense & Military : Equipment like radars, weapons systems, and communication devices are exposed to desert conditions. Larger sand dust test chambers replicate battlefield like dust storms to validate durability.

- Electronics & Semiconductors : Circuit boards, connectors, and enclosures are tested to ensure resistance to dust particles that could cause short circuits or failure.

- Renewable Energy Sector : Solar panels and wind turbine components are evaluated against sand erosion and dust accumulation to ensure long term energy efficiency.

Advantages of Using Larger Capacity Chambers

When compared to smaller dust test chambers, the larger sand and dust test chamber in the USA offers several unique advantages:

- Test more specimens in one cycle, saving time and operational costs.

- Ability to test large industrial products like automotive engines, generators, and aerospace panels.

- Uniform dust concentration ensures accuracy and repeatability.

- Flexible designs support both standard and customized testing requirements.

Accessories for Sand and Dust Chambers

To support versatile testing, our chambers come with specialized accessories:

- Talcum Powder : Particle size 45μm for standardized dust tests.

- Nichrome Temperature Heater (2000W+) : Ensures controlled heating.

- Vacuum Pump System : For sealing validation and leak detection.

- Observation Windows with Wipers : Allow real time visibility without interruption.

Sand and Dust Test Chamber Cost Considerations

The sand and dust test chamber cost depends on factors like chamber size, level of customization, and accessories included. Larger chambers typically cost more due to their size and added functionalities. However, they deliver better ROI (Return on Investment) by enabling large-scale testing in fewer cycles.

Testron offers competitive pricing in the USA, ensuring clients receive high-quality environmental chambers at industry-best value. Our products balance durability, accuracy, and affordability, making us one of the most reliable sand and dust test chamber manufacturers worldwide.

Why Larger Capacity Makes a Difference in a Sand Test Chamber

While traditional dust test chambers are sufficient for small components, industries are increasingly demanding larger sand and dust chambers for testing bulkier products.

- A 1500L or 2000L chamber allows simultaneous testing of multiple units, reducing turnaround time.

- Aerospace and automotive companies in the USA use these larger chambers to test entire assemblies instead of small samples.

- Larger chambers also provide a more uniform dust distribution, ensuring test accuracy and repeatability.

This scalability is one reason why sand and dust test chamber manufacturers in the USA are seeing increasing demand for high capacity chambers.

Compliance with International Standards for Sand and Dust Chamber

A major advantage of investing in a sand dust test chamber is its ability to replicate internationally recognized test methods. Testron’s larger sand and dust test chamber in the USA complies with:

- IEC 60529 (Ingress Protection Testing)

- ISO 20653 (Road Vehicle Protection against Dust)

- MIL-STD-810G (Environmental Engineering Considerations for Military Equipment)

- ASTM D1735 and ASTM D2247 for controlled exposure

These standards make our sand test chamber solutions suitable for USA manufacturers who export globally, ensuring that their products meet both domestic and international certification requirements.

Comparing Sand and Dust Test Chamber Cost vs Value

For USA companies evaluating the sand and dust test chamber cost, it is crucial to consider both short-term price and long-term ROI.

- Initial Cost : Larger capacity chambers (1500L:2000L) have a higher upfront investment compared to smaller models.

- Operational Savings : They allow testing of multiple specimens at once, reducing electricity, labor, and time costs.

- Longevity of Equipment : By preventing field failures, companies save millions in warranty claims and recalls.

- Regulatory Compliance : Avoid penalties or rejections in defense, aerospace, and automotive tenders.

Thus, while sand and dust test chamber price may seem high, its long term value far outweighs the investment.

Why Choose Testron Group in the USA?

- Trusted Manufacturer : Recognized globally as one of the leading sand and dust test chamber manufacturers.

- USA Centric Support : Local service and calibration support for American industries.

- Custom Solutions : Tailored designs for unique applications.

- Proven Compliance : All chambers comply with ISO, IEC, and MIL standards.

- Long Term Reliability : Built with robust stainless steel construction and advanced airflow systems

Frequently Asked Questions

What is a larger sand and dust test chamber used for?

A larger chamber is used to simulate dust and sand exposure on large or multiple products, ensuring durability and compliance with industry standards.

What industries need sand and dust chambers in the USA?

Automotive, aerospace, electronics, defense, construction, and consumer electronics industries rely on these chambers for testing.

How much does a sand and dust test chamber cost?

The sand and dust test chamber cost varies depending on capacity (1500L or 2000L), features, and customization. Testron offers competitive pricing for USA clients.

Are custom designs available for specific testing needs?

Yes, Testron provides custom sand dust chambers tailored to client specific requirements.

What standards do Testron’s sand and dust chambers comply with?

Our chambers comply with IEC60529, ISO20653, and MIL-STD-810G, ensuring global test compatibility.

Why should I choose Testron as my chamber supplier?

Testron is a trusted sand and dust test chamber manufacturer and supplier, offering high quality equipment, competitive pricing, and USA based support.