Description

Dust and sand ingress can severely impact the performance and longevity of critical components. The sand and dust IP test chamber recreates natural desert-like conditions, where fine particles are suspended and circulated under controlled airflow and temperature. These tests help determine if seals, enclosures, and protective coatings can withstand long-term exposure to sand and dust without compromising function or safety.

The Testron IP5X and IP6X sand and dust IP test chamber units are specifically designed for IP ratings that evaluate protection against solid particles. IP5X testing assesses dust protection where partial ingress is allowed, while IP6X testing ensures complete dust-tight sealing. With multiple chamber capacities ranging from 800 to 2000 liters, Testron’s sand and dust IP chamber options cater to various testing requirements, from small electronics to large automotive assemblies.

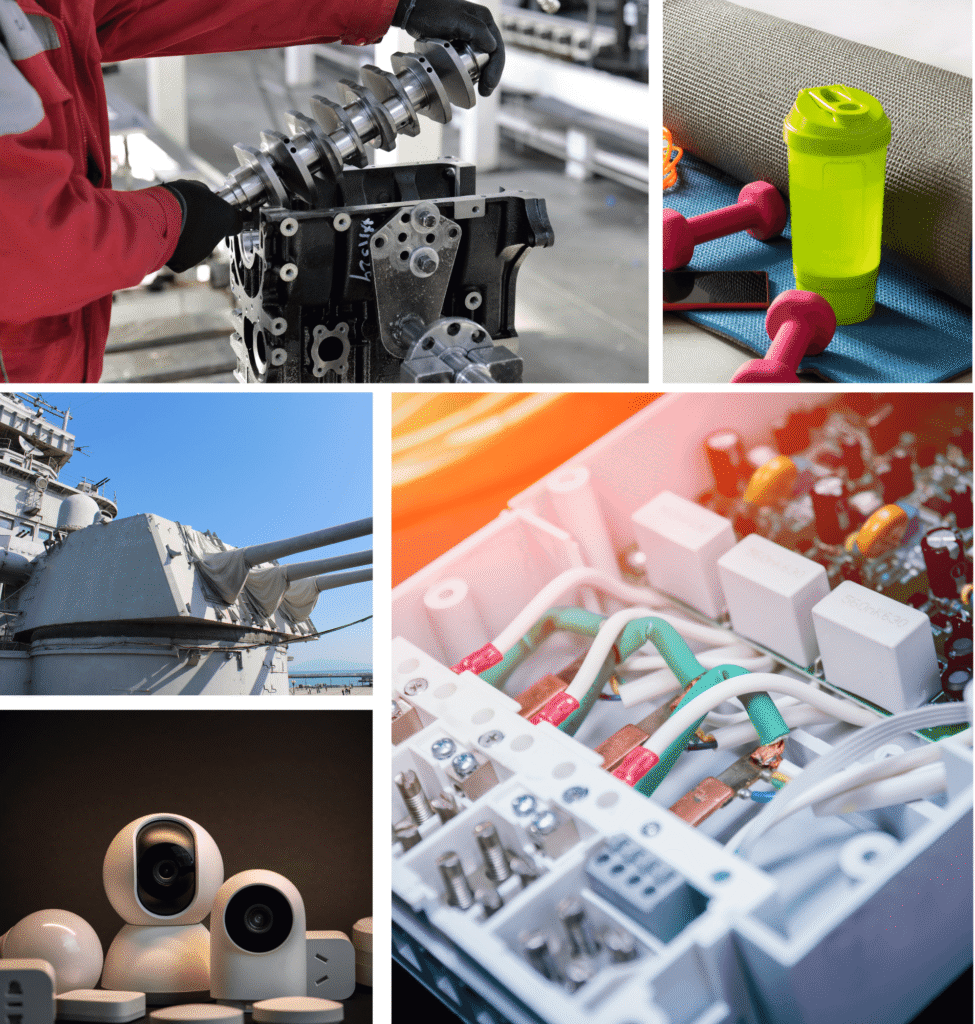

Applications of the Sand and Dust IP Test Chamber in the USA

- Automotive lighting, control systems, and engine components

- Defense and aerospace equipment for field performance testing

- Electronic devices and sensors requiring ingress protection validation

- Outdoor and industrial equipment exposed to dusty environments

- Consumer electronics such as cameras, smartphones, and GPS units

Key Features of the Testron Sand and Dust IP Test Chamber

When considering the sand and dust IP test chamber cost, it is important to look at the advanced features included in our sand and dust IP test equipment:

- Designed in accordance with IEC 60529 and ISO 20653 standards

- Available in IP5X and IP6X configurations for versatile testing

- Talcum powder particle size: 45 μm for consistent test conditions

- Even airflow circulation system to maintain uniform dust distribution

- Adjustable dust concentration (2–4 kg/m³) for customizable test environments

- Programmable touch-screen controller with Ethernet connectivity

- Temperature control up to +50°C for realistic test simulations

- Durable stainless-steel construction for long operational life

- Viewing window and interior illumination for real-time observation

- Overheat and overcurrent safety protection systems

- CE marked and ISO17025 calibrated

Technical Specifications for the Sand and Dust IP Chamber

| Model | Internal Dimensions (mm) | Overall Dimensions (mm) | Temperature Range | Talcum Powder Amount |

|---|---|---|---|---|

| DI-800 | 800 × 1000 × 1000 | 1040 × 1450 × 1960 | Ambient to +50°C | 2–4 kg/m³ |

| DI-1000 | 1000 × 1000 × 1000 | 1200 × 1450 × 1960 | Ambient to +50°C | 2–4 kg/m³ |

| DI-1500 | 1000 × 1500 × 1000 | 1250 × 1900 × 1960 | Ambient to +50°C | 2–4 kg/m³ |

| DI-2000 | 1000 × 2000 × 1000 | 1300 × 2400 × 1960 | Ambient to +50°C | 2–4 kg/m³ |

Accessories Included with Your Sand and Dust IP Test Equipment

Each sand and dust IP test chamber in the USA comes equipped with essential accessories to ensure immediate operation:

- Talcum powder (45 μm particle size)

- High-efficiency nichrome temperature heater (2000 W and above)

- Air circulation fans for controlled dust flow

- Reusable sealing gaskets for specimen ports

- Data logging and reporting software for precise test documentation

- Cable feed-through ports with silicone plugs

Working Principle of the Sand and Dust Test Chamber

The sand and dust IP chamber operates by circulating dust particles in a controlled airflow environment. The air and dust mixture is blown upward from the bottom of the chamber, simulating desert wind conditions. The specimens are exposed to these circulating particles for a predetermined duration to evaluate the level of dust ingress. The programmable controller regulates airflow velocity, dust concentration, and temperature to ensure repeatable results.

In IP5X testing, partial dust ingress is permissible, but the internal components must not be affected. In IP6X testing, no dust ingress is allowed, verifying that the enclosure provides complete protection. These tests are essential for ensuring the operational reliability of products exposed to outdoor or industrial conditions.

Advantages of Using a Sand and Dust IP Test Chamber in the USA

Investing in a reliable sand and dust IP test chamber provides several business and technical benefits:

- Guarantees compliance with international ingress protection standards

- Enhances product durability and reliability for outdoor applications

- Reduces field failures and warranty claims by identifying weak seals early

- Ensures safety of electronic and mechanical components in dusty environments

- Supports product development, validation, and certification processes

- Provides repeatable, controlled, and efficient testing results

Why Choose Testron as Your Sand and Dust IP Test Chamber Manufacturer

Testron Group stands as a trusted sand and dust IP test chamber manufacturer in the USA, offering top-quality chambers that combine advanced engineering with user-centric design. Our chambers are used by leading automotive and electronics manufacturers across the country who demand precision and consistency from their environmental chamber setups.

- Over two decades of expertise in environmental testing technology

- Customizable models to suit different product sizes and test needs

- Competitive sand and dust IP test chamber price with superior quality assurance

- Comprehensive after-sales support, training, and calibration services

- Durable materials and energy-efficient components reducing long-term sand and dust IP test chamber cost

- Integration with data acquisition systems for real-time monitoring and control

Testing Standards Supported

- IEC 60529: Defines degrees of protection provided by enclosures (IP Code)

- ISO 20653: Specifies protection of road vehicles from water and dust ingress

- MIL-STD-810: Used for military-grade dust and sand exposure testing

These standards ensure that every product tested in a sand and dust IP testing chamber meets stringent performance requirements expected by global industries.

Choosing the Best Sand and Dust IP Test Chamber for Your Facility

Selecting the right sand and dust IP test chamber supplier involves evaluating key factors such as chamber size, dust circulation rate, control accuracy, and compliance requirements. For manufacturers conducting regular IP testing, investing in a programmable, high-capacity IP test chamber offers long-term sand and dust IP test chamber cost benefits and faster turnaround times.

Testron provides consultation and customization to ensure that clients receive the best sand and dust IP test chamber in the USA suited to their specific applications. Whether you’re testing small sensors or large automotive parts, we deliver tailored solutions backed by advanced automation and reliability.

Maintenance and Calibration

Proper maintenance ensures the longevity and accuracy of your sand and dust IP test equipment. Testron offers preventive maintenance programs, calibration services, and replacement parts to keep your chamber operating at peak performance. Our USA-based support team provides quick technical assistance, ensuring minimal downtime and continuous test reliability.

Frequently Asked Questions

What is the purpose of a sand and dust IP test chamber?

It evaluates the resistance of components to dust and sand exposure, helping determine their IP rating for dust ingress protection.

What standards are supported by Testron’s dust chambers?

Our chambers comply with IEC 60529, ISO 20653, and MIL-STD-810 standards for IP5X and IP6X testing.

How does the sand and dust test chamber simulate real conditions?

The chamber circulates dust particles with controlled airflow, temperature, and duration, simulating natural desert environments for accurate testing results.

What factors affect the sand and dust IP test chamber price?

Chamber size, control system features, and test automation influence the overall sand and dust IP test chamber cost.

Can small electronic devices be tested in these chambers?

Yes, our chambers are available in various capacities, including compact models suitable for testing smaller components and devices.

How often should the chamber be serviced?

We recommend periodic maintenance and annual calibration to maintain testing accuracy and equipment reliability.