Salt Spray Test Chambers for Quality & Corrosion Resistance Testing in the USA

When it comes to evaluating the corrosion resistance and surface durability of metals, coatings, and protective finishes, a salt spray test chamber in the USA is one of the most essential pieces of equipment for any quality control or R&D laboratory. Whether you are a QC manager overseeing compliance with ASTM B117, ISO 9227, and other salt spray corrosion test standards, or a quality test manager ensuring your products meet customer expectations, investing in a high-performance chamber from a trusted salt spray chamber manufacturer can make all the difference in product reliability and lifecycle performance.

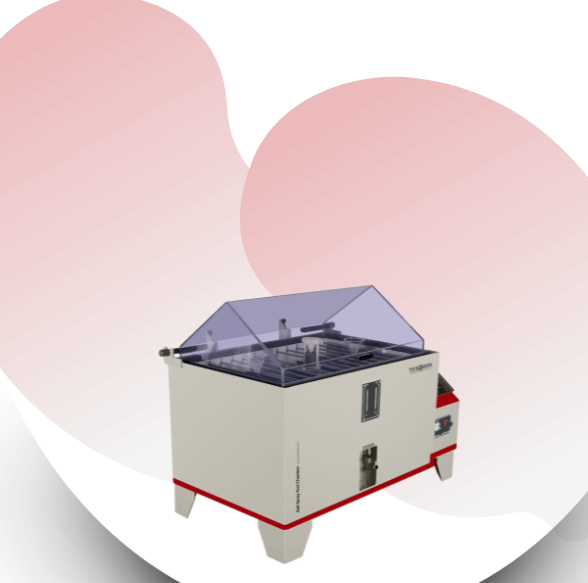

Testron Group offers a full range of salt spray chambers, from basic salt spray corrosion chambers for standardized ASTM/ISO testing, to cyclic salt spray chambers capable of simulating multiple environmental conditions in a single test sequence. Our chambers are designed for consistent, repeatable results while keeping salt spray chamber cost competitive and providing unmatched build quality, precision, and after sales support across the USA.

Why Salt Spray Testing Matters for Quality Assurance

Corrosion not only reduces a product’s appearance but also compromises its structural integrity. Salt spray testing chambers and environmental chambers allow QC teams to simulate years of environmental exposure in a matter of days or weeks, providing valuable data on coatings, paints, platings, and metallic substrates. Industries such as automotive, aerospace, electronics, marine, and construction rely heavily on a salt spray test chamber in the USA to ensure compliance with strict corrosion performance requirements. .

By working with experienced salt spray chamber suppliers like Testron Group , manufacturers in the USA can ensure that their testing process adheres to recognized salt spray corrosion test chamber standards, minimizing the risk of product failure in the field.

Testron Salt Spray Test Chamber in the USA Models & Capabilities

Designed for straightforward, standardized corrosion testing, the basic salt spray chamber is ideal for routine quality checks and accelerated testing under constant salt fog exposure.

- Meets global standards : ASTM B117, ISO 9227, IEC, and more

- Capacities : From 108L to 1600L

- Temperature range: Ambient to 60°C

- Salt spray deposition: 1–2 ml / 80cm²·h

- Standard features: Transparent lid for sample observation, hydrostatic hood seal, temperature and salt fog controls, CE mark, ISO17025 calibration

For advanced corrosion simulation, the cyclic salt spray chamber combines salt fog exposure with humidity , drying , and temperature cycling in programmable sequences.

- Meets accelerated corrosion standards : ASTM B117, ASTM G85, ISO 9227, IEC 60068 2-52, ISO 7253

- Temperature range : +10°C to +90°C

- Humidity range : 30% RH to 98% RH

- Advanced controls : Programmable LCD touch screen, Ethernet access, USB data export

- Optional features : SO₂ gas dosing, custom dimensions, enhanced corrosion resistance materials

- Ideal for : Automotive component testing, marine grade material validation, long term durability studies

Advantages of Choosing Testron Salt Spray Chambers in the USA

- Compliant with leading salt spray test standards

- Competitive salt spray chamber price with uncompromising build quality

- Custom sizes and configurations available for unique testing needs

- Durable construction using corrosion resistant materials

- User friendly interface for simplified operation

- Reliable after sales service and calibration support across the USA

- Trusted by leading QC managers and salt spray test chamber manufacturers worldwide

Applications of Salt Spray Testing Chambers

- Automotive body panels, fasteners, and coating validation

- Aerospace component corrosion assessment

- Marine equipment resistance to saltwater environments

- Electronics housing and PCB protective coating testiNg

- Construction materials and protective finish evaluation

- Paint, plating, and anodizing quality verification

Testron Salt Spray Test Chambers

Buying Guide – Selecting the Right Salt Spray Chamber

When selecting a salt spray corrosion test chamber or salt spray test chamber in the USA, consider:

Testing Standard Compliance

Ensure it meets ASTM B117, ISO 9227, or industry specific standards.

Capacity Requirements

Choose a chamber size that accommodates your sample dimensions and batch volumes.

Testing Type

Decide between basic continuous fog exposure or advanced cyclic testing.

Budget vs. Features

Compare salt spray chamber prices and salt spray chamber cost against feature sets and longevity.

Supplier Support

Work with reputable salt spray test chamber suppliers that provide calibration, installation, and after sales service.

Basic Vs. Cyclic Salt Spray Corrosion Test Chambers

When selecting the right corrosion testing system, buyers must consider test complexity and the specific requirements of a salt spray test chamber in the USA. While a basic salt spray corrosion test chamber is ideal for standardized, single-environment testing and routine quality validation, a cyclic salt spray corrosion chamber expands testing capabilities with programmable environmental shifts that simulate real-world exposure.Industries such as automotive, aerospace, marine, and infrastructure increasingly prefer cyclic systems due to their enhanced correlation to field conditions, while manufacturers requiring repeatable, controlled ASTM B117 benchmarks often choose the basic model for certification and mass-production validation. Both systems maintain global compliance and automated operation, making the decision dependent on testing objectives rather than machine quality.

Additionally, the cyclic system offers greater predictive accuracy when assessing long-term component failure patterns, coating adhesion stability, and accelerated ageing trends. Meanwhile, basic chambers remain the most cost effective choice for the routine QC testing where high throughput, compliance, and simplicity matters more than environmental complexity.

For teams working within strict regulatory frameworks or supplying government contracts, choosing between the two chamber types often comes down to the expected environmental exposure of the end-use application. For example, components used in coastal installations, marine hardware, offshore platforms, and defense-grade systems typically require cyclic salt spray testing because it more accurately represents exposure to condensation, salt fog, temperature fluctuations, and intermittent drying. On the other hand, industries producing fast-moving consumer goods, hardware fittings, coatings, and plating materials may favor basic salt spray chambers due to their simplicity, fast test turnaround, and predictable operational workflow.

Operational capacity planning also plays a role. Laboratories with high test volume demands or multi-material comparison workflows generally find greater efficiency using cyclic chambers because of their programmability and expanded test sequencing. Meanwhile, smaller facilities or R&D labs conducting repetitive ASTM B117 compliance tests may benefit from the straightforward setup and lower operational learning curve of basic chambers. Ultimately, both systems provide reliable, repeatable corrosion testing performance:- the key difference lies in whether the testing objective is to verify a standard specification or simulate decades of environmental wear in a controlled, accelerated format.

| Feature Category | Basic Salt Spray Corrosion Test Chamber | Cyclic Salt Spray Corrosion Test Chamber |

|---|---|---|

| Primary Use | Standardized continuous salt fog exposure | Multi-environment cyclic accelerated corrosion testing |

| Compliance | ASTM B117, ISO 9227, IEC | ASTM B117, ASTM G85, ISO 9227, IEC 60068-2-52, ISO 7253 |

| Testing Modes | Constant salt spray only | Salt spray, humidity, drying, temperature cycling |

| Temperature Range | Ambient to 60°C | +10°C to +90°C |

| Humidity Control | Not available | Fully programmable (30%–98% RH) |

| Control System | Standard controls | Programmable LCD touchscreen with Ethernet & USB |

| Material | Standard corrosion-resistant construction | Glass-fiber reinforced corrosion-resistant enclosure |

| Add-On Features | Optional custom sizes | Optional SO₂ gas dosing, expanded environmental programming |

| Best Application | Routine QC testing, coatings, electroplating validation | Automotive, marine, aerospace, long-term durability simulation |

| Available Capacities | 108L – 1600L | Multiple scalable industrial test chamber sizes |

| Ideal Users | Manufacturers, QC labs, basic certification environments | R&D labs, compliance facilities, reliability engineering teams |

Frequently Asked Questions

What is a salt spray test chamber used for ?

A salt spray chamber is used to evaluate the corrosion resistance of materials, coatings, and surface treatments by exposing them to a controlled salt fog environment under specific temperature and humidity conditions.

What standards do Testron salt spray chambers comply with ?

Our salt spray corrosion test chambers comply with ASTM B117, ISO 9227, IEC 60068-2-52, and other international corrosion testing standards.

How much does a salt spray test chamber cost in the USA ?

The salt spray chamber price in the USA varies depending on capacity, features, and configuration. Basic models are more affordable, while advanced cyclic salt spray chambers have higher investment costs due to added functionality.

What’s the difference between basic and cyclic salt spray chambers ?

A basic salt spray chamber provides constant salt fog exposure, while a cyclic salt spray chamber can alternate between salt fog, humidity, drying, and temperature cycles for more realistic environmental simulations.

Who are the main users of salt spray testing chambers ?

Salt spray test chamber manufacturers, automotive companies, aerospace firms, marine equipment producers, paint and coating manufacturers, and third party testing labs use these chambers for quality assurance.

Can I get custom sized salt spray chambers ?

yes, as a leading salt spray chamber manufacturer, Testron provides custom configurations to meet specific testing needs and sample sizes.