Salt Spray Chamber Price in the USA: Complete Cost Breakdown, Specifications & What Buyers Should Know

Salt Spray Chamber Price & Cost Factors

Salt spray testing has become a critical quality assurance requirement across industries including automotive manufacturing, marine engineering, aerospace, hardware production, electronics, and surface finishing. As regulatory and performance expectations increase, companies across the USA are actively investing in corrosion testing solutions—particularly high-performance salt spray chambers.

This guide provides a complete breakdown of the salt spray chamber price in the USA, including cost variations based on configuration, capacity, features, materials, automation level, and compliance standards. It also covers real-world applications, model comparisons, purchasing factors, and how Testron Group – one of the most trusted salt spray chamber manufacturers and salt spray chamber suppliers—supports laboratories with advanced reliability testing systems.

If you are evaluating a salt spray test machine price, salt fog chamber price, salt spray test chamber price, or salt spray cabinet price, this article will help you, with support from the Testron Group, make an informed and cost-efficient procurement decision.

Why Salt Spray Testing Matters in the USA Market

Salt spray testing simulates years of exposure to harsh conditions in a controlled environment. A salt spray test chamber in the USA enables QC teams to evaluate corrosion resistance according to the required salt spray chamber standards under::

- Salt fog exposure

- Marine or coastal environments

- High humidity and moisture conditions

- Accelerated material aging

Industries that rely heavily on salt spray testing include:

- Automotive parts manufacturing

- Aerospace components

- Marine ships and offshore equipment

- Electrical and electronic assemblies

- Coatings, paint, and plating manufacturers

- Hardware, construction, and fastener production

Companies across Los Angeles, Detroit, Houston, Chicago, New York, Miami, Dallas, Phoenix, Seattle, and Boston use corrosion testing to validate reliability before products reach consumers or regulatory review. Understanding the full salt spray chamber price is crucial for budget planning.

Salt Spray Chamber Models Available in the USA

Testron Group offers two major solutions depending on testing requirements, which directly impact the final salt spray chamber cost.:

| Model Type | Best For | Salt Spray Chamber Cost Range (USA Market Estimate) |

| Basic Salt Spray Test Chamber | Routine corrosion testing, ASTM B117 compliance | Entry-range to mid-range investment level depending on capacity and automation |

| Cyclic Salt Spray Test Chamber | Advanced multi-environment corrosion simulation | Mid-range to premium investment tier depending on capacity and features |

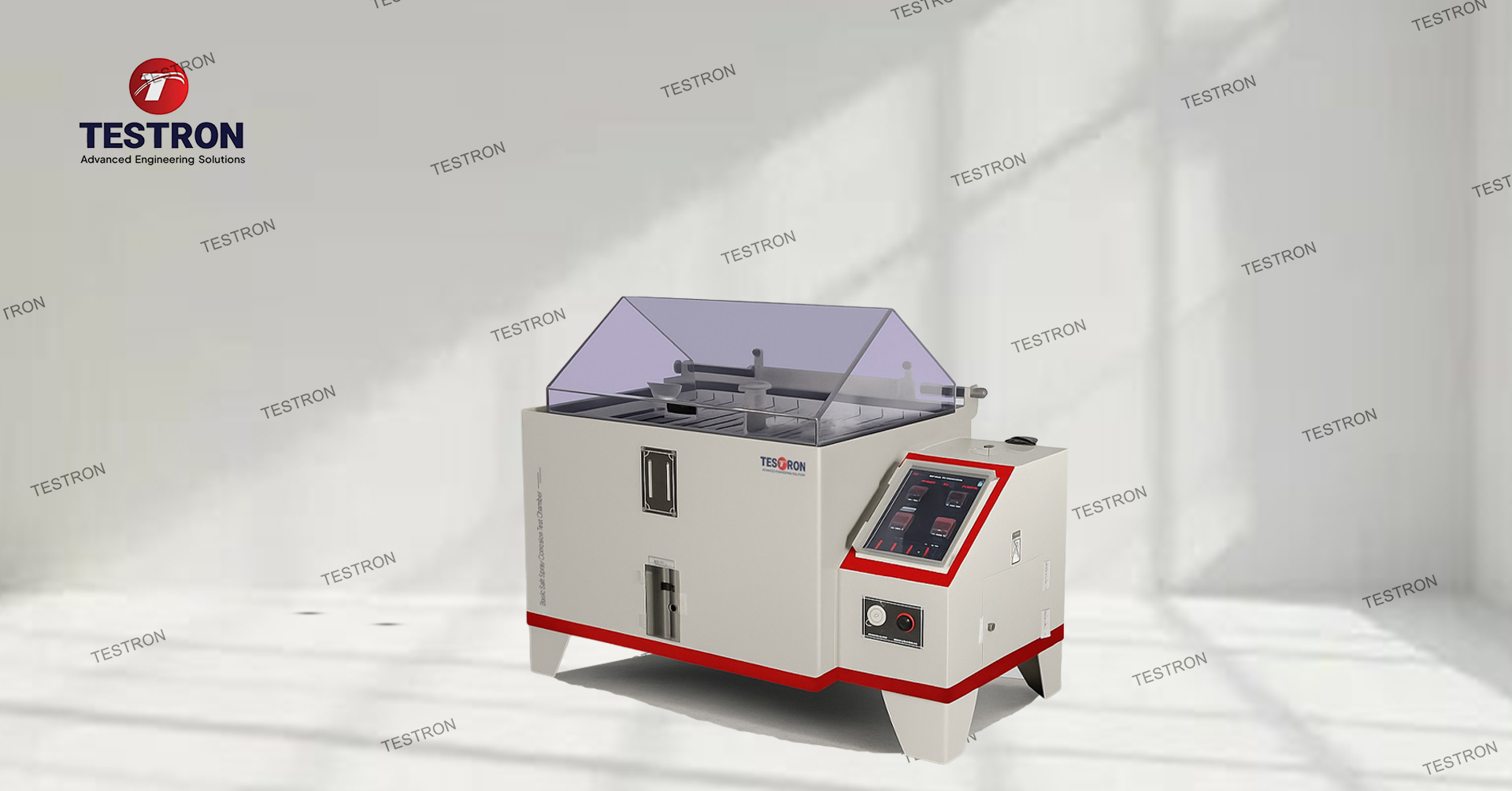

Basic Salt Spray Corrosion Test Chamber

This model is ideal for companies requiring standardized testing with consistent salt fog exposure. It is widely used for product validation benchmarks where the primary focus is the salt spray corrosion test chamber price versus compliance.

Key Features:

- Compliant with ASTM B117, ISO 9227, IEC Standards

- Capacities: $108\text{L} – 1600\text{L}$

- Temperature range: Ambient $\rightarrow 60^\circ\text{C}$

- Salt deposition rate: $1\text{–}2 \text{ ml}/80\text{cm}^2$ per hour

- Transparent lid for real-time observation

- Hydrostatic hood seal

- ISO 17025 calibration included

Cyclic Salt Spray Chamber (Advanced Testing)

Designed for accelerated and multi-phase corrosion testing. This chamber simulates real-world weather cycles including:

- Salt Fog

- Drying

- Temperature Cycling

- High Humidity

- Condensation

The added complexity means a higher salt fog chamber price.

Key Capabilities:

- ASTM B117, ASTM G85, ISO 9227, IEC 60068-2-52 compliance

- Temperature range: +10°C to +90°C

- Humidity: 30%–98% RH

- Optional SO₂ gas dosing

- Programmable LCD controller

- USB/Ethernet export and remote data access

This environmental chamber is typically selected by automotive, aerospace, marine, and defense industries that require advanced environmental simulation rather than single-condition corrosion exposure.

Salt Spray Chamber Price in the USA: Full Cost Breakdown

Several factors influence the final salt spray chamber price in the USA and should be carefully considered during procurement.:

| Cost Factor | Influence on Price |

| Chamber Capacity (108L to 1600L+) | Larger chambers cost more |

| Type (Basic vs Cyclic) | Higher functionality increases price |

| Compliance Standards | ASTM/ISO capabilities increase value |

| Automation & Data Logging | Cloud connectivity and smart software add cost |

| Material Construction | Corrosion-resistant high-grade components increase durability and cost |

| Optional Features | Gas dosing, custom fixtures, fog uniformity tuning |

General Price Range Estimate (USA Market)

While exact quotations depend on configuration, capacity, controls, and optional engineering specifications, the typical salt spray test machine price generally ranges from mid-tier to advanced pricing tiers depending on features and size.

Why Choose Testron Group as Your Salt Spray Chamber Manufacturer in the USA?

Testron Group is recognized as a leading salt spray chamber manufacturer and supplier with U.S.-based support, compliance documentation, and calibration services. They provide competitive pricing without compromising on the quality and compliance needed for the USA market.

Why U.S. quality managers prefer Testron:

- ISO-certified components

- ASTM B117 and ISO 9227 compliance

- Industrial-grade materials for long-term durability

- Remote service support and annual calibration

- Customization options for aerospace, automotive, and marine programs

Top Industries Using Salt Spray Test Chambers in the USA

The investment in a salt fog test chamber is justified by the critical reliability validation it provides across major sectors.

| Industry | Use Case |

| Automotive | Coating durability, metal part corrosion resistance |

| Aerospace & Defense | Structural corrosion, aluminum fatigue, surface treatment reliability |

| Marine Manufacturing | Saltwater and galvanic corrosion testing |

| Electronics & Electrical | PCB coating validation, connector corrosion |

| Construction Materials | Outdoor material and fastener certification |

Related: Learn more about corrosion test chambers in the USA

Real-World Case Study: KLUDI Rak (UAE)

(Referenced from: Testron Group Success Stories)

KLUDI Rak used Testron’s salt spray test chamber to validate corrosion-resistant bathroom fittings for long-term environmental exposure simulation. KLUDI Rak found the chamber provided highly repeatable test results, increasing product reliability and reducing warranty claims. This mirrored USA customer expectations in coastal markets such as Florida, New Jersey, California, and Texas, demonstrating the value of investing in the right salt spray cabinet price.

Buying Checklist for U.S. Laboratories

Before finalizing a purchase, verify the following to ensure you select the best chamber for the optimal salt spray machine price, verify:

- ASTM B117 and ISO 9227 certification support

- Software reporting and traceability compliance

- Fog dispersion uniformity

- Available chamber volume versus future scalability

- After-sales support response time

- On-site calibration and spare parts availability

CALL TO ACTION

Are you ready to purchase or compare salt spray test machine price options?

Read more: Discover Testron’s Advanced Environmental Chambers in the USA

Frequently Asked Questions

What affects the salt spray test chamber price in the USA the most?

Capacity, automation, test compliance standards, and advanced cyclic testing options have the greatest influence.

Is a basic chamber enough for corrosion testing?

Yes: if your testing is standardized (ASTM B117). Cyclic testing is needed for advanced simulation.

What industries benefit most from salt spray chambers?

Automotive, marine, aerospace, semiconductor, electronics, and coating manufacturers.

Are salt spray chamber suppliers offering calibration and installation?

Yes: Testron offers installation, calibration, software setup, and lifelong servicing.

Can Testron customize chamber size or features?

Yes: custom dimensions, gas dosing, racks, monitoring cameras, and automation add-ons are available.