Description

Why Choose a UV Test Chamber in the USA?

Investing in a UV test chamber in the USA is no longer optional for USA-based manufacturers competing in industries where product quality and compliance are critical. Choosing a high-quality UV weathering test chamber or UV light test chamber ensures:

- Ensures compliance with ASTM, ISO, and GM weathering standards.

- Replicates years of outdoor UV exposure in just weeks.

- Prevents premature failures such as fading, cracking, or oxidation.

- Reduces warranty claims and boosts customer confidence.

- Supports R&D, quality assurance, and certification processes.

- Available at competitive UV test chamber prices tailored to USA market needs.

Key Features of Testron UV Weathering Chambers

Our UV accelerated weathering testers and UV light test chambers are designed to deliver precision, repeatability, and compliance:

- Equipped with UVA-340 and UVB-313 fluorescent lamps for full-spectrum testing.

- Temperature range: Ambient to +90℃ with BPT control from 35℃ to 80℃.

- Humidity simulation ≥95% RH for combined UV + moisture effects.

- Programmable color LCD touchscreen controller for easy operation.

- Ethernet, PC link, and USB connectivity for data logging and remote access.

- Automatic water supply and purification system for long-term operation.

- Safety features including over-temperature, over-current, and water shortage protection.

- Standard compliance: ASTM G154, ASTM D4329, ISO 4892, and more.

Applications of UV Light Test Chambers

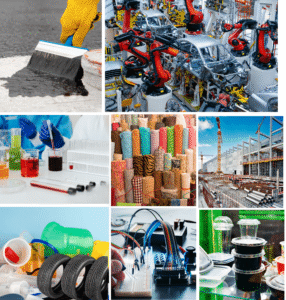

Testron’s UV weather test chambers and UV weathering test chambers are widely used across different sectors:

- Automotive and Aerospace: testing paints, coatings, interiors, and polymers for UV resistance.

- Plastics and Rubber: ensuring product durability under prolonged sun exposure.

- Textiles & Fabrics: evaluating fading, strength loss, and color stability.

- Coatings & Paints: assessing gloss loss, chalking, blistering, and cracking.

- Construction Materials: simulating long-term durability of roofing, siding, and composites.

- Electronics: testing plastic housings, displays, and components exposed to UV light.

- Packaging: ensuring labels, inks, and films retain print clarity and performance.

- Solar Energy Sector: testing photovoltaic modules for UV degradation.

Factors to Consider Before Buying a UV Weathering Test Chamber

When selecting the right UV test chamber price package, USA buyers should evaluate:

- Size & capacity: from benchtop UV test cabinets to large-format chambers.

- Lamp type: UVA-340 for sunlight spectrum or UVB-313 for accelerated damage.

- Compliance needs: ASTM, ISO, and other specific test standards.

- Budget & operating costs: upfront UV weathering test chamber prices vs. long-term ROI.

- Manufacturer reliability: working with trusted UV weathering test chamber manufacturers ensures durability and after-sales service.

- Customization options: chambers tailored for specific industries like coatings, automotive, or textiles.

Benefits of UV Environmental Test Chambers in the USA

By choosing Testron’s UV weathering chambers and UV light test chambers, you gain:

- Accurate simulation of outdoor sunlight with repeatable results in your UV test chamber in the USA.

- Compact UV test cabinet options for laboratories with limited space.

- Flexible water spray and condensation cycles for real-world replication in an accelerated UV weathering chamber.

- Energy efficient design, lowering operational costs.

- Affordable UV weathering test chamber prices for USA buyers.

- Long service life with minimal maintenance needs.

- Backed by Testron’s expert service as a leading UV weathering test chamber manufacturer.

Comparative Table: Types of UV Test Chambers in the USA

| Model | Chamber Size (mm) | Lamp Type | Temperature Range | Applications | UV Test Chamber Price Range (USA) |

|---|---|---|---|---|---|

| TT-UVA260 | 450×1170×500 | UVA-340 / UVB-313 | Ambient to +90℃ | General R&D, Plastics, Coatings | Affordable entry-level |

| TT-UVA500 | 600×1400×600 | UVA-340 High Output | Ambient to +95℃ | Automotive & Aerospace | Mid-range |

| TT-UVA1000 | 1000×2000×800 | UVA & UVB Combo | Ambient to +100℃ | Construction, Textiles, Solar Panels | Premium-tier |

Testron: Leading UV Weathering Test Chamber Manufacturer in the USA

Testron Group is proud to be among the most reliable UV weathering test chamber manufacturers serving the USA. Our UV light test chambers and UV weathering test chambers are engineered with precision, tested for durability, and designed to support industries that demand accuracy.

As a top UV weathering test chamber manufacturer, we understand the specific needs of USA industries. That’s why our UV accelerated weathering testers and UV weathering chambers combine advanced technology with affordability.

Future Needs for UV Weathering Resistance Test Chambers

The future demand for UV Weathering Resistance Test Chambers is being shaped by global trends in product quality, sustainability, and material innovation. As industries strive to enhance product durability and ensure compliance with stricter testing standards, the UV weathering test chamber and the broader use of the environmental chamber will become an indispensable tool for research and quality control.

1. Increased Focus on Accelerated Material Testing

With the rapid development of new polymers, coatings, and composites, industries such as automotive, construction, packaging, and aerospace are seeking faster and more accurate ways to predict long-term material performance. Future UV test chambers will feature advanced irradiation control systems and multi-spectrum testing capabilities, allowing simultaneous simulation of various real-world weathering conditions like UV exposure, humidity, and condensation.

2. Smart Control and Data Integration

As part of Industry 4.0 transformation, future UV weathering resistance test chambers will integrate IoT-based monitoring systems, Ethernet connectivity, and AI-assisted control software. These advancements will enable real-time tracking of test parameters, predictive maintenance alerts, and remote operation, improving both efficiency and test reliability.

3. Energy Efficiency and Sustainability

Environmental compliance is becoming a global mandate. Future UV chambers will incorporate energy-saving LED-based UV sources, improved insulation materials, and optimized water circulation systems to minimize energy and water consumption. Such sustainable designs will help companies meet green manufacturing goals without compromising testing accuracy.

4. Customization and Application-Specific Testing

Industries have unique testing requirements: for example, automotive coatings require high-intensity UV exposure, while packaging materials may need lower irradiance but longer humidity cycles. The future will see an increasing demand for custom-built UV weathering chambers with adjustable chamber sizes, programmable test cycles, and flexible lamp configurations to match specific industry needs.

5. Compliance with Evolving Global Standards

As international testing standards such as ASTM, ISO, and GM continue to evolve, UV weathering test chambers will be designed for multi-standard compliance. Future models will feature automatic parameter calibration and validation tools to ensure accurate, repeatable, and traceable results for global certification and export requirements.

6. Integration with Advanced Analytics

The next generation of UV test chambers in the USA will include data analytics platforms capable of analyzing trends in gloss loss, color fading, and material degradation. This integration will enable R&D teams to make data-driven improvements in material formulations and predict product lifespan more precisely.

Frequently Asked Questions

What is the purpose of a UV test chamber?

A UV test chamber replicates years of outdoor UV, heat, and moisture exposure in a controlled environment to test material durability.

What types of lamps are used in UV weathering test chambers?

Most chambers use UVA-340 (closest to sunlight) and UVB-313 (accelerated damage simulation).

How much does a UV test chamber cost in the USA?

The UV test chamber price varies by size, features, and compliance standards , ranging from affordable lab models to large industrial chambers.

Which industries use UV accelerated weathering testers?

They are used in automotive, aerospace, plastics, coatings, textiles, electronics, and construction industries.

How long does testing take in a UV weathering chamber?

Accelerated testing can simulate months or years of outdoor exposure in just a few weeks.

Why choose Testron UV weathering chambers in the USA?

Because we are a UV weathering test chamber manufacturer providing reliable performance, competitive pricing, and USA focused service.