Description

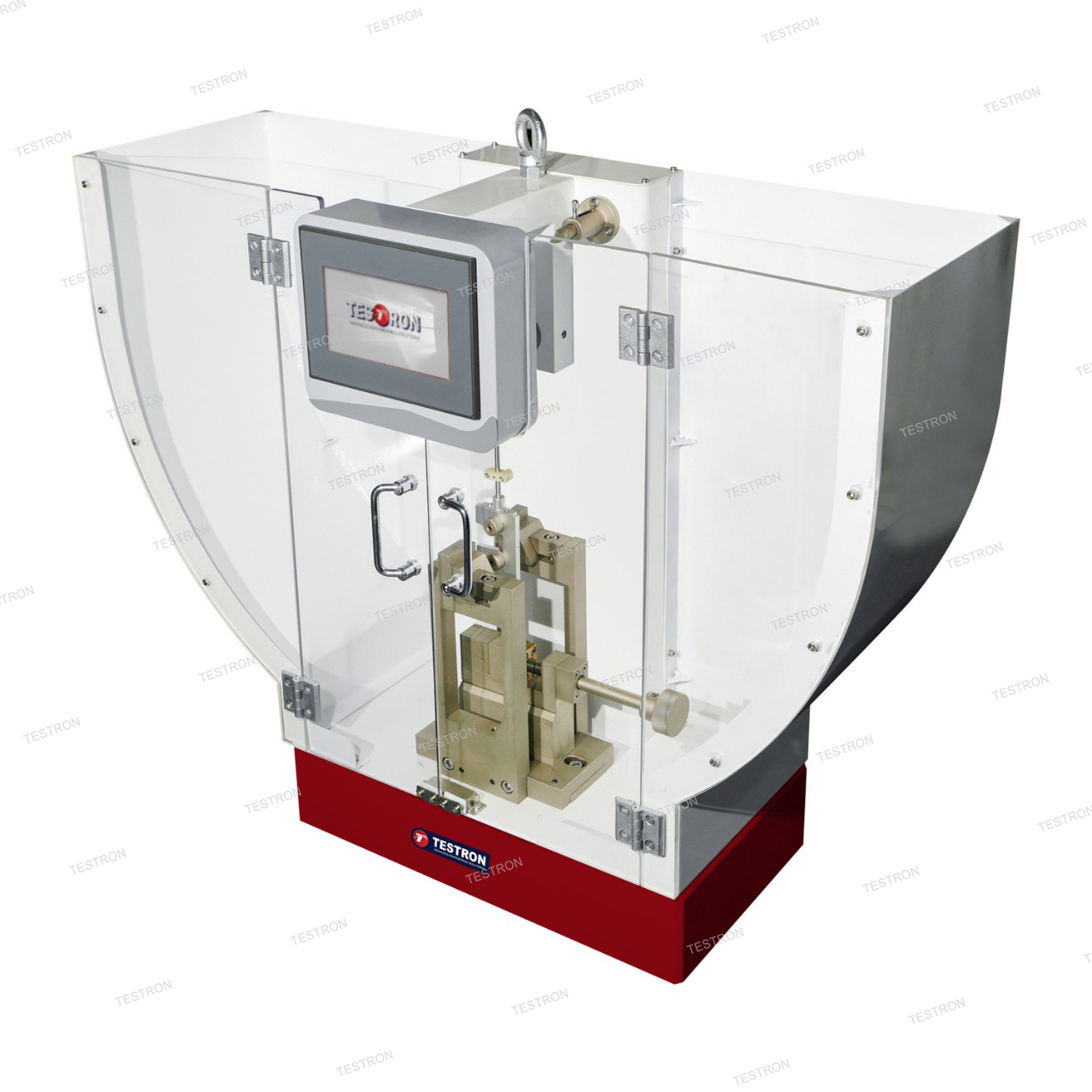

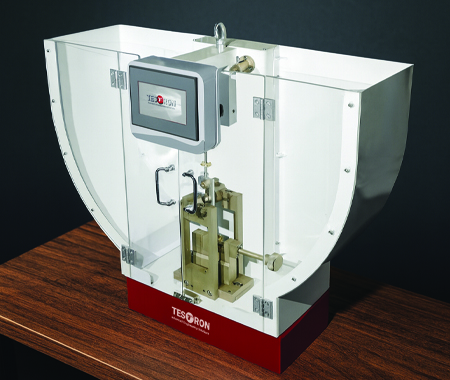

With advancements in manufacturing automation, testing repeatability requirements, and international certification frameworks, U.S. laboratories need more than a basic testing system. They need a complete solution that offers reliability, speed, accuracy, calibration support, and compliance. This is where Testron Group’s advanced charpy impact tester machine stands out. Developed to align with ISO, ASTM, and global industry requirements, this instrument is engineered for performance stability, laboratory safety, and high-volume sample throughput.

As one of the leading charpy impact testing machine manufacturer and charpy impact testing machine supplier options in the USA, Testron Group provides highly accurate and user-focused systems that help laboratories streamline impact strength testing across plastics, metals, polymer composites, wires, rigid pipes, engineering resins, construction materials, aerospace components, and specialized R&D materials.

Why U.S. Laboratories and Industries Choose a Charpy Impact Testing Machine in the USA

Organizations across the United States—from private research institutes to federal compliance labs—depend on reliable impact testing technology. A properly designed charpy impact testing machine in the USA ensures:

- Repeatable and standardized energy absorption measurement using a charpy impact test machine.

- Reduction of operator-based variability with a precision charpy impact tester.

- High-accuracy pendulum impact velocity via a charpy pendulum impact tester.

- Reliable fracture behavior comparison between material batches using a charpy impact test apparatus.

These benefits make a charpy pendulum impact tester essential not only for routine quality inspection but also for failure analysis, forensic investigations, product development comparison studies, and certification workflows across sectors like automotive, aerospace, medical plastics, and defense-grade materials.

Key Benefits of Using a Charpy Impact Testing Machine in the USA

A modern charpy impact test equipment system delivers significant value for U.S. labs through:

- High-speed pendulum accuracy ensuring precise fracture evaluation

- Controlled clamping systems minimizing specimen alignment errors

- Long-term calibration stability and repeatable energy readings

- Compatibility with rigid materials including HDPE, PVC, ABS, PP, metals, thermosets, pipes, and composite materials

Whether measuring brittle fracture transitions or evaluating comparison performance between multiple formulations, the best charpy impact testing machine ensures consistency and laboratory-grade repeatability.

Core Applications of a Charpy Impact Testing Machine in the USA

The versatility of a charpy impact test equipment setup makes it applicable in:

- Plastic and polymer characterization

- Pipe impact strength validation

- Construction and infrastructure material qualification

- Automotive and aerospace structural testing

- Metal and composite toughness evaluation

- Academic, government, and industrial research

The charpy impact testing machine in the USA remains a global standard because it is simple, fast, and highly comparable across laboratories when executed using compliant equipment.

Technical Excellence and Engineering Reliability

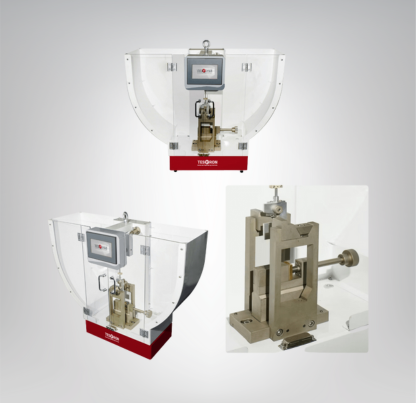

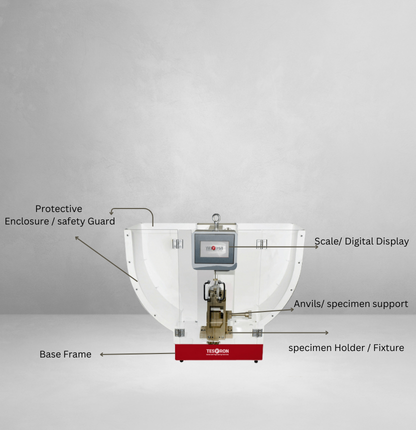

One of the most notable advantages of our charpy impact testing machine in the USA is its engineering construction. The pendulum hammer, supports, and energy measurement mechanism of the charpy impact test machine are precision-machined from high-strength alloys, ensuring impact accuracy even after thousands of repetitive test cycles. The frame of the charpy impact tester machine is vibration-resistant, ensuring stable readings and preventing testing deviation.

The charpy impact test apparatus aligns with international requirements including:

- ISO 179

- ASTM E23

- DIN and industry-specific impact standards

This ensures that laboratories performing global compliance or third-party validation testing can trust the consistency of the results provided by this charpy impact testing machine manufacturer.

Understanding Charpy Impact Testing Machine Price and Value

When buyers evaluate the charpy impact testing machine price or the charpy impact test machine price, factors such as calibration consistency, build quality, automation features, pendulum accuracy, safety framework, and long-term maintenance requirements become more important than the initial cost. A high-precision charpy impact tester system reduces failed testing runs, saves operator time, and improves material qualification reliability—resulting in an excellent return on investment. Whether you are looking for a competitive charpy impact testing machine price or a charpy impact test machine price that reflects premium features, value is found in durability.

How to Select the Best Charpy Impact Testing Machine in the USA

Decision-makers comparing systems from a charpy impact testing machine supplier should consider:

- Impact energy capacity

- Automation support

- Data acquisition compatibility

- Safety features and operator ergonomics

- Standard compliance certifications

- Maintenance and calibration support availabilit

- Machine longevity and component durability

These factors ensure the chosen charpy impact testing machine supplier provides real testing value.

Features That Make Testron a Trusted Charpy Impact Test Machine Manufacturer

Testron Group is one of the most reliable charpy impact testing machine manufacturers and charpy impact testing machine supplier brands serving U.S. testing environments. Our charpy impact test machine and charpy impact tester machine are trusted by government-certified laboratories, aerospace research bodies, polymer processing companies, and educational engineering labs.

Key advantages include:

- Precision-engineered spindle with stable RPM control

- Industrial motion control software with advanced accuracy algorithms

- Reinforced machine base to minimize vibration and deflection

- Compatibility with multiple tooling and materials

Future Role of Charpy Impact Testing Equipment in Emerging U.S. Industries

With advancements in sustainable materials, artificial intelligence-assisted material development, and additive manufacturing, the charpy impact testing machine in the USA remains a cornerstone of validation. A best charpy impact test machine ensures materials remain safe, fracture-resistant, and capable of withstanding environmental or mechanical stress. As a leading charpy impact testing machine supplier, we ensure our charpy impact tester technology evolves with these industries.

Frequently Asked Questions

What materials can be tested using a Charpy impact tester?

The machine supports plastics, rigid pipes, metals, composites, and polymer materials used in industrial and research environments.

Does the machine comply with international standards?

Yes, the system complies with ISO 179, ASTM, DIN, and industry-specific requirements.

What affects the Charpy impact testing machine price?

The charpy impact testing machine costs are Automation level, pendulum capacity, safety design, software integration, and calibration accuracy.

Can the Charpy impact tester be customized for unique industry applications?

Yes, custom fixtures, pendulum types, and automation systems are available.

Does Testron provide installation, user training, and calibration support?

Yes:-full assistance and ongoing service support are provided in the U.S.

Is this tester suitable for high-volume laboratory environments?

Absolutely: the machine is engineered for continuous operation and repeatable testing cycles.

Key Technical Features

Ready to enhance your material testing precision?

Request a quote for the best Charpy impact testing machine in the USA.

Ask for customization, demo access, or technical specifications.