Description

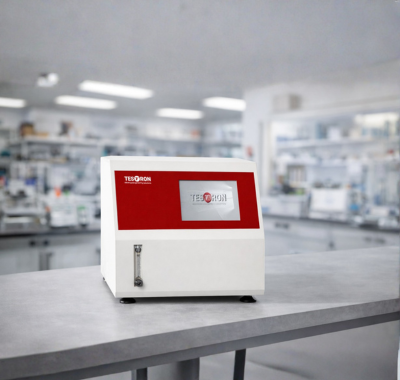

As a trusted name among carbon black content tester manufacturers, Testron delivers equipment that balances technical accuracy with long-term reliability. Whether used in production quality control, third-party testing labs, or research environments, the TT-900E provides dependable carbon black measurement that helps organizations maintain compliance, reduce material failure risk, and ensure consistent product performance.

Why Carbon Black Content Testing Is Critical in the USA

Carbon black plays a vital role in enhancing polymer performance, especially in outdoor and pressure-rated applications common across U.S. infrastructure projects. Accurate carbon black content ensures proper UV stabilization, resistance to environmental degradation, and long-term mechanical integrity. Too little carbon black can lead to premature ageing and cracking, while excessive carbon black may negatively affect material processing and strength.

A precision carbon black content tester in the USA enables manufacturers to verify raw materials, monitor extrusion consistency, and certify finished products before market release. Regulatory frameworks and customer specifications increasingly require documented carbon black content verification, making reliable carbon black testing equipment a non-negotiable component of modern quality systems.

Industries producing HDPE pipes, telecom ducts, electrical cables, geomembranes, and pressure fittings depend on accurate carbon black measurement to meet ASTM, ISO, IEC, and regional standards. The TT-900E ensures these requirements are met with repeatable, traceable, and audit-ready results.

TT-900E Carbon Black Content Testing Machine – Engineered for Precision

The TT-900E is a high-performance carbon black content testing machine designed to determine carbon black concentration through controlled combustion under oxygen and nitrogen environments. This carbon black content test apparatus uses programmable temperature profiles and precision gas control to deliver accurate and repeatable measurements.

With an integrated heating furnace and control system, the TT-900E simplifies operation while maintaining strict temperature uniformity. Its LED display and PID programmable temperature control allow operators to create, store, and execute up to 30 temperature programs with a single command. This design makes the TT-900E an efficient and user-friendly carbon black content testing instrument for U.S. laboratories performing routine and high-volume testing.

The system supports rapid heating, controlled atmosphere switching, and optional rapid cooling to improve laboratory throughput. These features make it one of the best carbon black content tester options for organizations seeking both accuracy and operational efficiency.

Supported Carbon Black Content Test Standards

Compliance with international and industry-recognized test methods is essential when selecting a carbon black content tester supplier. The TT-900E is designed to support widely accepted carbon black content test standard requirements, including ISO and IEC protocols commonly used in the United States.

The tester complies with ISO 6964, IEC 60811-4-1, and relevant GB and transportation testing standards. These standards are used to evaluate carbon black content in polymer materials for pipes, cables, and industrial plastics. By supporting these test frameworks, the TT-900E carbon black content tester in the USA enables manufacturers to certify products for domestic use and global export markets.

Applications of Carbon Black Content Testing Equipment

The TT-900E carbon black testing equipment is widely used across industries that require accurate polymer material validation. Its applications include polyethylene and polypropylene pipe manufacturing, cable insulation testing, telecom conduit production, geomembrane quality verification, and polymer research laboratories.

This carbon black tester is commonly deployed in pipe testing laboratories to verify UV stability and long-term durability of HDPE and PP pipes used in water supply, gas distribution, and infrastructure projects. Electrical and telecom cable manufacturers rely on precise carbon black measurement to ensure insulation performance and safety compliance.

Research institutions and material development labs also use the TT-900E to evaluate new polymer formulations and masterbatch consistency. Its versatility makes it a valuable asset across production, R&D, and certification environments.

Key Features of the TT-900E Carbon Black Content Tester

The TT-900E integrates advanced thermal control, gas management, and safety features to deliver reliable testing results. Its programmable LED display supports up to 30 temperature segments with automatic memory storage, enabling consistent repeat testing.

The integrated furnace and control system design simplifies operation and reduces setup time for this specialized pipe testing equipment. Automatic switching between nitrogen and oxygen gas environments ensures accurate combustion control, supported by a high-precision floating ball gas flowmeter. The optional rapid cooling device improves test cycle efficiency, making it ideal for high-throughput U.S. laboratories.

The double doorknob furnace door design allows safe and convenient sample handling, while nano-blanket insulation material delivers excellent thermal insulation and temperature uniformity. These features collectively position the TT-900E as one of the best carbon black content tester solutions available.

Technical Performance and Build Quality

The TT-900E offers a temperature range from ambient to 1000 °C, suitable for a wide variety of polymer materials. Its furnace tube dimensions support standard sample sizes used in pipe and cable testing. The resistance wire heating element ensures stable temperature performance, while PID programmable control maintains accuracy across extended test cycles.

Designed for laboratory reliability, the system operates on standard AC power and features a compact footprint with durable construction. As a dependable carbon black content testing instrument, it delivers consistent performance with minimal maintenance, making it a long-term investment for U.S. testing facilities using a carbon black content tester in the USA.

Understanding Carbon Black Content Tester Price in the USA

When evaluating carbon black content tester price, U.S. buyers consider factors such as temperature capability, automation level, gas control accuracy, compliance support, and long-term durability. While initial cost is important, laboratories must also consider repeatability, calibration stability, and service support.

The TT-900E offers excellent value by combining advanced features with competitive pricing. As a reliable carbon black content tester supplier, Testron ensures that customers receive strong after-sales support, documentation, and operational guidance, maximizing return on investment.

Why Choose Testron as Your Carbon Black Content Tester Manufacturer

Testron Group is globally recognized for delivering precision material testing solutions tailored to industrial and laboratory needs. As one of the trusted carbon black content tester manufacturers, Testron focuses on accuracy, durability, and user-centric design.

U.S. customers benefit from application-specific configuration support, reliable spare parts availability, and expert technical assistance. This commitment to quality and service makes Testron a preferred partner for organizations seeking dependable carbon black content testing equipment.

Carbon Black Content Tester in the USA for Consistent Quality and Long-Term Performance

In the competitive U.S. polymer manufacturing landscape, maintaining consistent material quality is critical for product reliability and brand reputation. The carbon black content tester in the USA plays a key role in verifying that polymer compounds meet strict performance and durability requirements before they reach the market. By accurately measuring carbon black concentration, manufacturers can prevent premature material failure, reduce warranty claims, and ensure compliance with customer and regulatory specifications.

The TT-900E carbon black content testing machine is designed to deliver repeatable and traceable results across multiple testing cycles. Its stable thermal environment and controlled gas flow ensure that each test reflects true material behavior rather than environmental variation. This level of accuracy is essential for U.S. quality assurance teams working with high-value applications such as pressure pipes, electrical insulation, and outdoor polymer components.

Enhancing Production Efficiency with Advanced Carbon Black Testing Equipment

Modern production environments demand testing equipment that is not only accurate but also efficient and easy to operate. The TT-900E carbon black testing equipment supports streamlined workflows through programmable temperature control and automated gas switching. Operators can store predefined test programs, allowing consistent testing across shifts and minimizing human error.

For manufacturers handling large sample volumes, this carbon black content testing instrument helps improve laboratory productivity without compromising result integrity. Optional rapid cooling further reduces downtime between tests, making it suitable for high-throughput environments where time and accuracy are equally important.

Reliable Carbon Black Content Test Apparatus for Compliance and Certification

Compliance with recognized carbon black content test standard requirements is essential for U.S. manufacturers supplying regulated markets. The TT-900E carbon black content test apparatus supports industry-recognized standards used in pipe, cable, and polymer testing laboratories. These standards ensure that test results are acceptable for audits, certifications, and third-party inspections. By integrating this carbon black content testing machine into their quality systems, manufacturers gain confidence that their products meet performance expectations under real-world conditions. This reliability is especially important for applications exposed to sunlight, temperature fluctuations, and mechanical stress over long service lifetimes.

Selecting the Best Carbon Black Content Tester for U.S. Laboratories

Choosing the best carbon black content tester requires careful consideration of accuracy, repeatability, ease of use, and long-term support. U.S. laboratories benefit from equipment that combines precision engineering with intuitive operation and dependable service availability. The TT-900E meets these expectations by offering advanced control features in a compact and durable design.

As a trusted carbon black content tester supplier, Testron ensures that customers receive not only high-quality equipment but also expert technical guidance. From initial setup to ongoing operation, U.S. users benefit from responsive support that helps maximize testing efficiency and equipment lifespan.

Long-Term Value and Carbon Black Content Tester Price Considerations

When evaluating carbon black content tester price, organizations should consider the total cost of ownership rather than upfront cost alone. Factors such as test repeatability, maintenance requirements, energy efficiency, and service support all contribute to long-term value. The TT-900E offers a balanced solution by delivering high-performance testing capabilities with low operational complexity.

As one of the experienced carbon black content tester manufacturers, Testron focuses on providing equipment that remains reliable over extended use. This approach ensures consistent testing results, reduced downtime, and strong return on investment for U.S. manufacturers and laboratories investing in a carbon black content tester in the USA.

Frequently Asked Questions

What is a carbon black content tester used for

A carbon black content tester in the USA is used to determine the percentage of carbon black in polymer materials to ensure UV resistance, durability, and compliance.

Which materials can be tested using the TT-900E

It is suitable for polyethylene, polypropylene, polybutene, and related polymer materials.

What standards does this carbon black content testing machine support

The TT-900E supports ISO 6964, IEC 60811-4-1, and other recognized carbon black content test standards.

What factors affect carbon black content tester price

Temperature range, automation level, gas control precision, compliance requirements, and service support influence pricing.

Is the TT-900E suitable for pipe and cable testing

Yes, it is widely used for HDPE pipes, plastic conduits, and cable insulation testing.

Why choose Testron as a carbon black content tester supplier

Testron offers precision engineering, reliable performance, competitive pricing, and strong U.S. technical support.

Call to Action

Ensure accurate polymer quality verification with a reliable carbon black content tester in the USA. Contact Testron Group today to request pricing, technical specifications, or expert consultation for the TT-900E carbon black content testing machine.