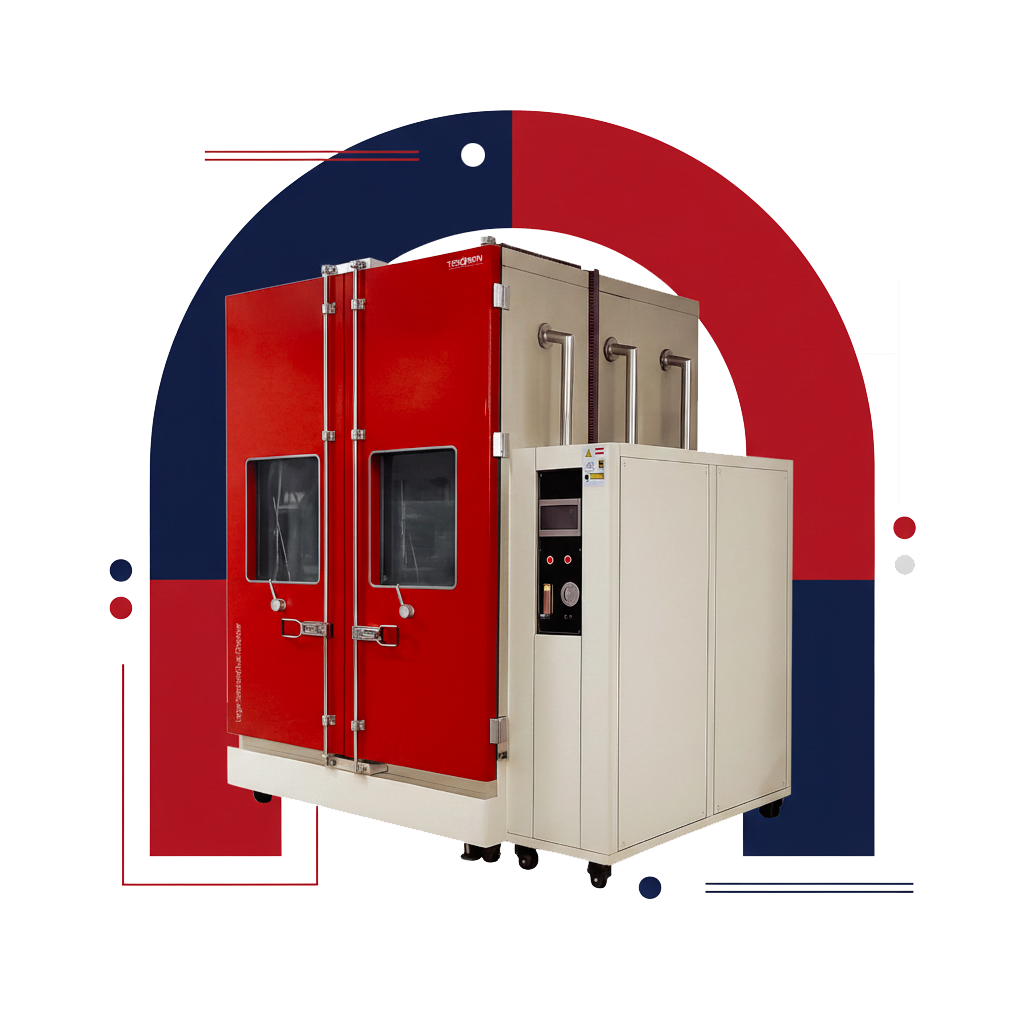

Introduction to IP Test Chambers

Ingress Protection (IP) ratings are critical for evaluating the durability and safety of electronic devices and enclosures. Testron Group offers a comprehensive range of IP Test Chambers that simulate various environmental conditions to test the resistance of products against solid particles (like dust) and liquids (like water).

Our IP Testing Chambers are engineered to meet the requirements of global standards such as:

- IEC 60529

- IS 12063

- JIS D0203

These chambers are essential for manufacturers in the automotive, electronics, telecommunications, consumer appliances, and defense sectors. With Testron’s solutions, companies can ensure that their products are robust, weatherproof, and compliant with international quality norms.

Why Choose

Testron Group Over Competitors?

In a crowded market, Testron Group stands out not just because of its superior engineering, but due to its holistic service ecosystem

Training & Installation

Every purchase includes on site training for your QC and R&D teams. Our technicians install the machine, calibrate the settings, and ensure operational excellence from day one.

Graphic Portfolio

We offer optional upgrades like:

- Adjustable jet nozzle diameters

- Programmable oscillation arms

- Multi product rotating platforms

- Heated water systems for extreme conditions

Pre Sales Consultation

Before recommending a chamber, our engineering team evaluates your specific product category, production volume, and compliance needs. This ensures you get a chamber tailored to your operations.

Service and AMC Support

We provide annual maintenance contracts and 48 hour service turnaround across India. Critical spare parts are stocked in regional warehouses, ensuring minimal downtime.

Advanced Features of Testron IP Test Chambers

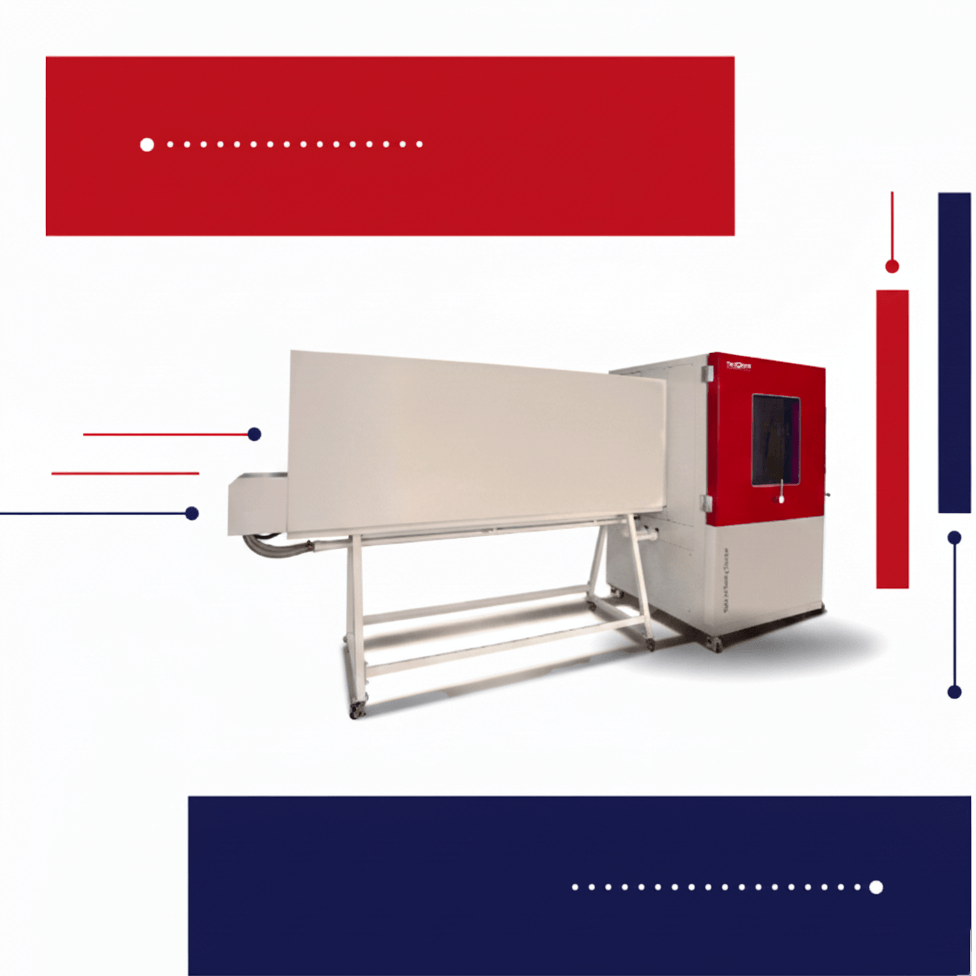

Testron Group’s IP test chambers are built to exceed industry expectations. The TT 3545 and TT-5565 models are designed with intuitive controls, precise environmental simulations, and safety first construction. Here are some of the standout features that set them apart

1.

Every Testron chamber is manufactured using corrosion resistant stainless steel, ensuring long term durability even under harsh conditions. Laser cut paneling and reinforced sealing guarantee that no external contaminants compromise the test results.

2.

The high pressure water nozzles are engineered for uniform coverage across the test sample surface. This is especially important for IPX5 and IPX6 testing, where consistent water jet application is essential for valid, repeatable results.

3.

Both chambers come with a responsive touchscreen control system that allows technicians to set parameters like water pressure, time duration, and rotational speed with ease. The interface logs data in real time and allows for remote monitoring and diagnostics via Ethernet or USB ports.

4.

Despite powerful motors and pumps, Testron IP chambers are engineered for low noise operation. They also feature energy efficient circulation systems that reduce operational costs without compromising performance.

5.

Testron IP test chambers fully comply with international testing standards such as:

- IEC 60529

- IS/IEC 60598-1

- JIS D 0203

- ISO 20653: 2013

- Automotive and Defense standards for ingress testing

Our equipment also adheres to CE and ISO 9001 manufacturing processes, ensuring consistent quality across every unit.

Testron IP Chambers

All Testron IP Test Chambers are manufactured in accordance with:

- IEC 60529

- IS 12063

- JIS D0203

- DIN 40050-9 (for IPX9K)

This ensures that every chamber can be used for third party certifications, in house product validation, or R&D testing.

Ingress Protection testing is not just a quality check , it is a commitment to product longevity, performance, and safety. It helps:

- Avoid field failures due to moisture or dust intrusion

- Enhance brand credibility by certifying compliance

- Meet regulatory and buyer requirements across global markets

- Reduce product recalls by validating durability under realistic conditions

Testron IP Test Chambers are designed to simulate rigorous environmental challenges, helping your product stand out as durable and reliable.

How IP Test Chambers Fit into Product Lifecycle Testing

For manufacturers in electronics, lighting, automotive, or telecommunications, ingress protection testing is not a single event,it’s part of an ongoing product development cycle. Testron’s chambers are ideal for:

- Prototype validation: During early stage development, IP testing can identify flaws in gasket sealing or enclosure design.

- Pre certification compliance: Prior to sending products to external certification agencies, in house testing with the TT-3545 or TT-5565 ensures that products are likely to pass.

- R&D and material testing: Companies experimenting with new enclosures or materials can use IP chambers to simulate wear and tear over time.

- Quality control: In production environments, randomly sampling batches for IP compliance ensures manufacturing consistency.

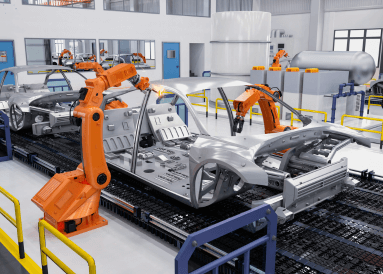

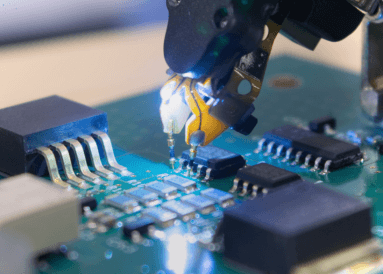

Industries We Serve in USA

Testron Group’s IP Test Chambers are trusted across various sectors:

Automotive

Testing components like headlamps, sensors, wipers.

Electronics & IoT

Smartphones, tablets, wearables, routers.

Telecom

Switches, modems, base stations.

Defense & Aerospace

Tactical devices, communication gear.

Consumer Appliances

Washing machines, hairdryers, microwaves.

Lighting

Outdoor LED fixtures, floodlights, solar lamps.

Choosing the Right IP Rating

Understanding IP Ratings is crucial when selecting the right test chamber. Here’s a breakdown

| IP Rating | Protection Against | Example Test |

|---|---|---|

| IPX1/X2 | Dripping Water | Simulated rain falling vertically/at angle |

| IPX3/X4 | Spraying Water | Oscillating tube or spray nozzles |

| IPX5/X6 | Water Jets | Powerful jets from all directions |

| IPX7/X8 | Immersion | Submersion at set depth and time |

| IPX9K | High pressure Jets | Steam cleaning simulation |

| IP5X/6X | Dust Ingress | Fine particles/vacuum suction tests |

Still unsure? Our experts are available to guide you in choosing the appropriate chamber.

Benefits of Using Testron IP Chambers

- Increased Product Reliability: Simulate real world dust and water exposure.

- Regulatory Compliance: Meet national and international certification standards.

- Reduced Warranty Claims: Catch failures before product release.

- Custom Engineering Support: Get chambers tailored to your unique product size and test requirement.

- Post Sale Technical Support: Training, maintenance, and annual calibration support.

Frequently Asked Questions

IP Test Chambers

How long does an IPX7 test last?

The standard test duration is 30 minutes of immersion in 1 meter deep water.

Can one chamber be used for multiple IP tests?

Yes, many of our chambers are modular and allow multi level testing (e.g., IPX3/4/5 in one unit).

What power source is required for IP chambers?

Typically, 230V single phase or 415V three phase power is required depending on the chamber size.

Are calibration certificates provided?

Yes, all chambers come with NABL traceable calibration certificates.

How much maintenance do these chambers need?

Very low. Regular cleaning and yearly calibration are sufficient under normal operating conditions.

Call to Action

Ensure your products stand the test of time and the elements.

Reach out to our team at www.testrongroup.com for a free consultation on the right IP Test Chamber for your business.

Need a custom chamber? We design, build, install, and support , all under one roof.

Book a live demo or request a brochure today.

Testron Group – Redefining Reliability Testing for Tomorrow’s Products.