Top Rated Charpy Impact Tester in the USA for Industrial, Research & QA Laboratories

Summary

Material failure under sudden impact can lead to catastrophic consequences—especially in industries such as aerospace, automotive, defense, construction, oil & gas, and advanced polymers. This is why a charpy impact tester in the USA remains one of the most critical material testing instruments for industrial manufacturers, research institutions, and quality assurance laboratories.

A charpy impact test machine evaluates a material’s ability to absorb energy during fracture when subjected to a high velocity impact. The data generated from a charpy impact tester equipmet is essential for determining toughness, brittleness, ductile to brittle transition behavior, and suitability for real world service conditions.

This in depth guide explains how U.S. buyers from Houston, Chicago, Detroit, Los Angeles, Boston, Cleveland, and Pittsburgh can select the right charpy impact test machine, evaluate specifications, compare prices, and choose a reliable charpy impact tester manufacturer and charpy impact tester supplier. It also highlights why Testron Group is recognized as a trusted provider of precision engineered charpy pendulum impact tester units designed for accuracy, compliance, and long term performance.

Why Charpy Impact Testing Is Critical for U.S. Industries

Across U.S. manufacturing hubs such as Detroit (automotive), Houston (energy), Los Angeles (aerospace), Chicago (steel and fabrication), and Boston (research & materials science), impact resistance testing is a mandatory requirement for safety, compliance, and product validation.

A charpy impact tester in the USA helps industries:

- Prevent brittle fracture failures

- Validate material performance at low temperatures

- Meet ASTM and ISO compliance requirements using a certified charpy impact test machine

- Improve product safety and reliability with a charpy impact tester machine

- Reduce recalls and field failures

With increasing regulatory scrutiny and material innovation, charpy impact test apparatus adoption continues to grow across industrial and research environments.

CTA: Download the Charpy Impact Tester Buyer’s Guide

What Is a Charpy Impact Tester?

A charpy impact tester is a mechanical testing instrument used to measure the energy absorbed by a notched specimen when fractured by a swinging pendulum. The absorbed energy indicates the material’s impact toughness. Because it is essential for verifying the strength of large-scale infrastructure materials, it is frequently utilized as a specialized pipe testing machine to evaluate the brittle-to-ductile transition of pipeline steels and industrial piping.

Key Components of a Charpy Impact Test Apparatus

- Heavy duty frame

- Charpy pendulum impact tester assembly

- Precision hammer and striker

- Specimen anvils

- Digital or analog energy measurement system

The charpy impact tester machine delivers fast, repeatable results that are critical for material qualification and quality assurance.

How the Charpy Impact Test Works

- A standard notched specimen is placed horizontally between two anvils in the charpy impact test apparatus.

- The pendulum of the charpy impact test machine is raised to a known height.

- The pendulum strikes the specimen at high velocity

- The energy absorbed during fracture is measured by the charpy impact tester machine.

This simple yet powerful test provides valuable insight into material behavior under sudden loading conditions.

Key Industries Using the Charpy Impact Tester in the USA

Metals & Steel Manufacturing

- Structural steel

- Pipelines

- Fasteners and forgings

Automotive & Transportation

- Chassis components

- Safety critical metal parts

- Polymer impact testing

Aerospace & Defense

- Aircraft alloys

- Defense grade composites

- Low temperature toughness evaluation

Plastics & Polymer Processing

- Engineering plastics

- Pipes and fittings

- Injection molded components

Research & Academic Laboratories

- Material characterization

- Failure analysis

- Advanced R&D programs

These applications demonstrate why charpy impact test equipment is indispensable in modern testing laboratories.

Charpy Pendulum Impact Tester vs Other Impact Tests

Test Method | Primary Use | Key Advantage |

Charpy Impact Test | Impact toughness | Simple, standardized |

Izod Impact Test | Plastics testing | Vertical specimen |

Drop Weight Test | Large components | Full scale impact |

Among these, the charpy pendulum impact tester remains the most widely accepted and standardized method globally.

Critical Specifications to Evaluate Before Buying a Charpy Impact Tester in the USA

When selecting a charpy impact tester in the USA, industry specialists must evaluate technical specifications carefully.

Key Technical Parameters

- Impact energy range (Joules)

- Pendulum capacity and accuracy

- Digital vs analog readout

- Specimen standards compatibility

- Calibration traceability

A reputable charpy impact tester manufacturer should clearly document these specifications.

ASTM & ISO Standards for Charpy Impact Test Apparatus

Compliance is non negotiable in U.S. testing environments. Testron’s best charpy impact test apparatus and charpy impact test machine are engineered to meet and exceed these commonly followed standards:

Commonly Followed Standards

- ASTM E23

- ISO 148 1

- ASTM A370 (for steel)

- EN standards (for global compliance)

Testron’s charpy impact test apparatus is engineered to meet and exceed these standards.

Charpy Impact Tester Price vs Long Term Value

While charpy impact tester price is an important consideration, experienced buyers focus on the total charpy impact tester cost and lifecycle value rather than just the upfront investment.

Factors That Influence Price

- Energy capacity

- Automation level

- Digital data acquisition

- Build quality and frame rigidity

- Calibration and service support

A lower charpy impact tester price may result in higher maintenance costs over time if accuracy and durability are compromised.

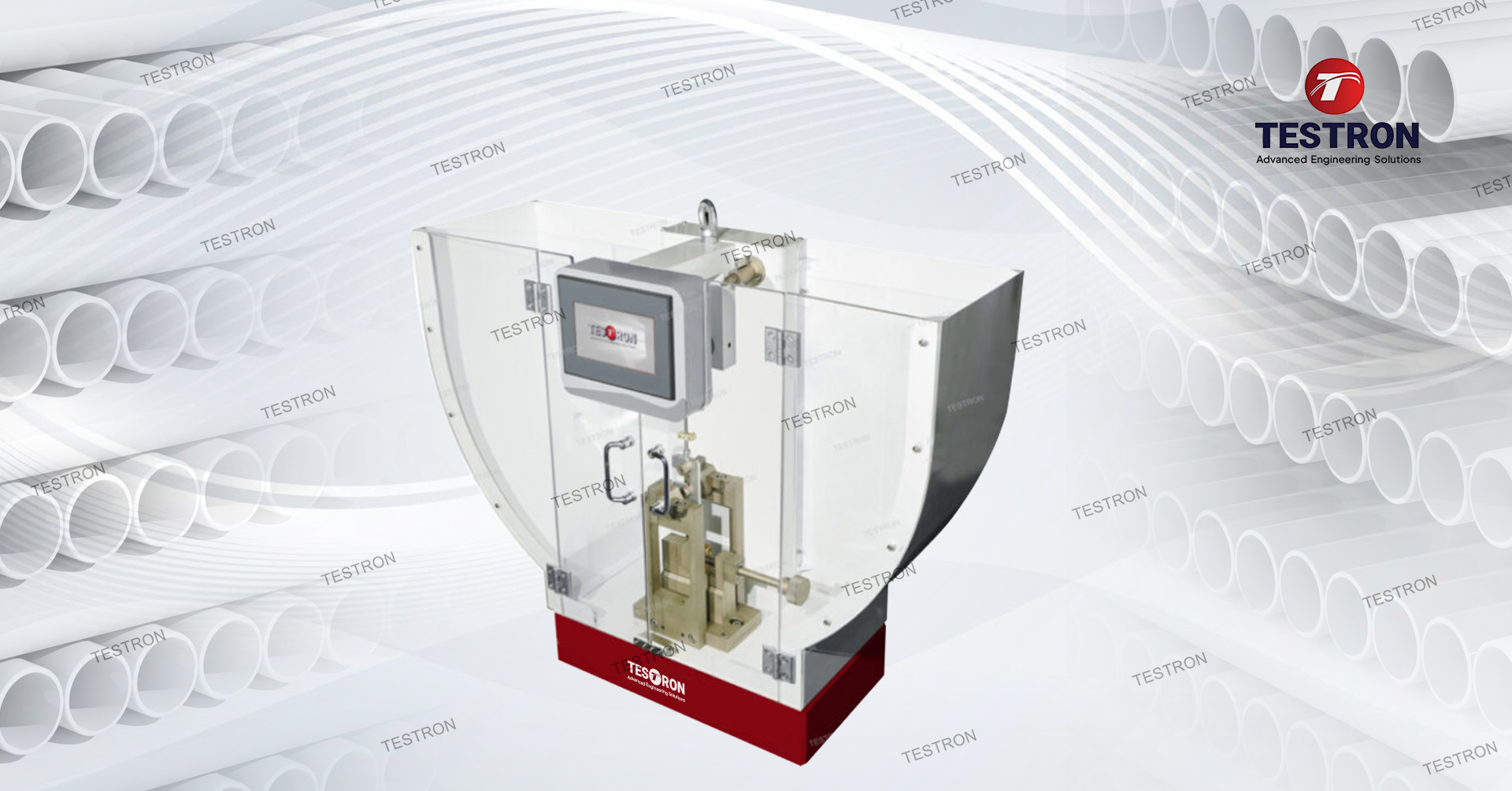

Why Testron Group Is a Trusted Charpy Impact Tester Manufacturer

Testron Group is a globally recognized charpy impact tester manufacturer and charpy impact tester supplier, serving customers across the USA, Europe, Middle East, and Asia.

Testron’s Competitive Advantages

- Precision engineered charpy pendulum impact testers

- ASTM & ISO compliant designs

- Robust mechanical construction

- High accuracy energy measurement

- User friendly operation

- Global service and calibration support

Our charpy impact tester in the USA is trusted by QA labs, research institutions, and industrial manufacturers alike.

Digital vs Manual Charpy Impact Tester Machines

Feature | Manual Tester | Digital Tester |

Readability | Analog scale | Digital display |

Data storage | Manual recording | Automatic logging |

Accuracy | Good | Excellent |

Audit readiness | Limited | High |

For regulated industries, a digital charpy impact tester equipment is often the preferred choice.

Installation, Calibration & After Sales Support

A reliable charpy impact tester supplier must offer more than just equipment. What buyers should expect from a charpy impact tester manufacturer includes:

What Buyers Should Expect

- Installation guidance

- Operator training

- ISO traceable calibration

- Spare parts availability

- Long term service support

Testron Group provides full lifecycle support to ensure uninterrupted testing operations.

Get a Charpy Impact Tester Quote

Download Technical Specifications

Speak with a Materials Testing Expert

Request a Live Demo

Conclusion

A top rated charpy impact tester in the USA is not just a testing instrument—it is a critical safeguard against material failure, safety risks, and compliance issues. By investing in the right charpy impact test equipment, industries can ensure consistent material performance, regulatory compliance, and long term operational confidence.

With precision engineering, global trust, and comprehensive support, Testron Group continues to be a preferred charpy impact tester manufacturer and charpy impact tester supplier for industrial, research, and QA laboratories across the United States.

Get Your Charpy Impact Tester Quote Today

Partner with Testron Group for Reliable Impact Testing

Frequently Asked Questions

What is a charpy impact tester used for?

It measures the impact energy absorbed by a material during fracture under sudden loading.

Which industries use charpy impact test machines in the USA?

Metals, automotive, aerospace, polymers, construction, and research laboratories.

What standards apply to charpy impact testing?

ASTM E23, ISO 148 1, and ASTM A370 are commonly followed.

How often should a charpy impact tester be calibrated?

Annual calibration or as required by QA protocols is recommended.

Why choose Testron Group as your charpy impact tester supplier?

Testron offers certified accuracy, robust engineering, and global service reliability.