Description

Why Temperature Cycling Tests Are Essential for Product Reliability

Modern products must endure fluctuating environmental conditions, freezing cold mornings, scorching heatwaves, and rapid temperature changes during transportation or operation. A temperature cycle test chamber accelerates these natural processes under controlled conditions, revealing how materials expand, contract, and respond to thermal stress over time.

Key benefits of performing tests with a temperature cycling test chamber include:

Detecting early signs of material fatigue, cracking, or delamination.

- Ensuring electronic components survive thermal shock and maintain connectivity.

- Validating structural integrity of metals, plastics, and composites.

- Enhancing product performance through data-driven R&D improvements.

- Meeting international testing standards like IEC, ASTM, and MIL-STD.

- Reducing warranty claims and improving overall product lifecycle.

Advanced Design and Working Principle of the Temperature Cycling Test Chamber

Testron’s thermal cycling test chamber integrates high-performance cooling and heating systems to provide rapid temperature change rates ranging from 1°C/min to 15°C/min. The chamber cycles between set high and low temperatures to reproduce real-world stress conditions.

The design includes an advanced programmable controller that allows users to pre-set test cycles within the environmental chamber, managing variables found in a temperature and humidity test chamber with extreme accuracy. The integrated mechanical compression refrigeration system ensures stability during rapid transitions, while the robust insulation minimizes energy loss. Each model is CE-marked and ISO17025-calibrated, ensuring international credibility for your temperature cycling test chamber in the USA.

Key Features of Testron’s Temperature Cycling Test Chamber

- Temperature ranges from -200°C (liquid nitrogen) to +180°C.

- Cooling rates between 1°C/min to 15°C/min for flexible test conditions.

- Multi-language programmable color LCD touchscreen controller.

- Ethernet and USB interfaces for data transfer and remote monitoring.

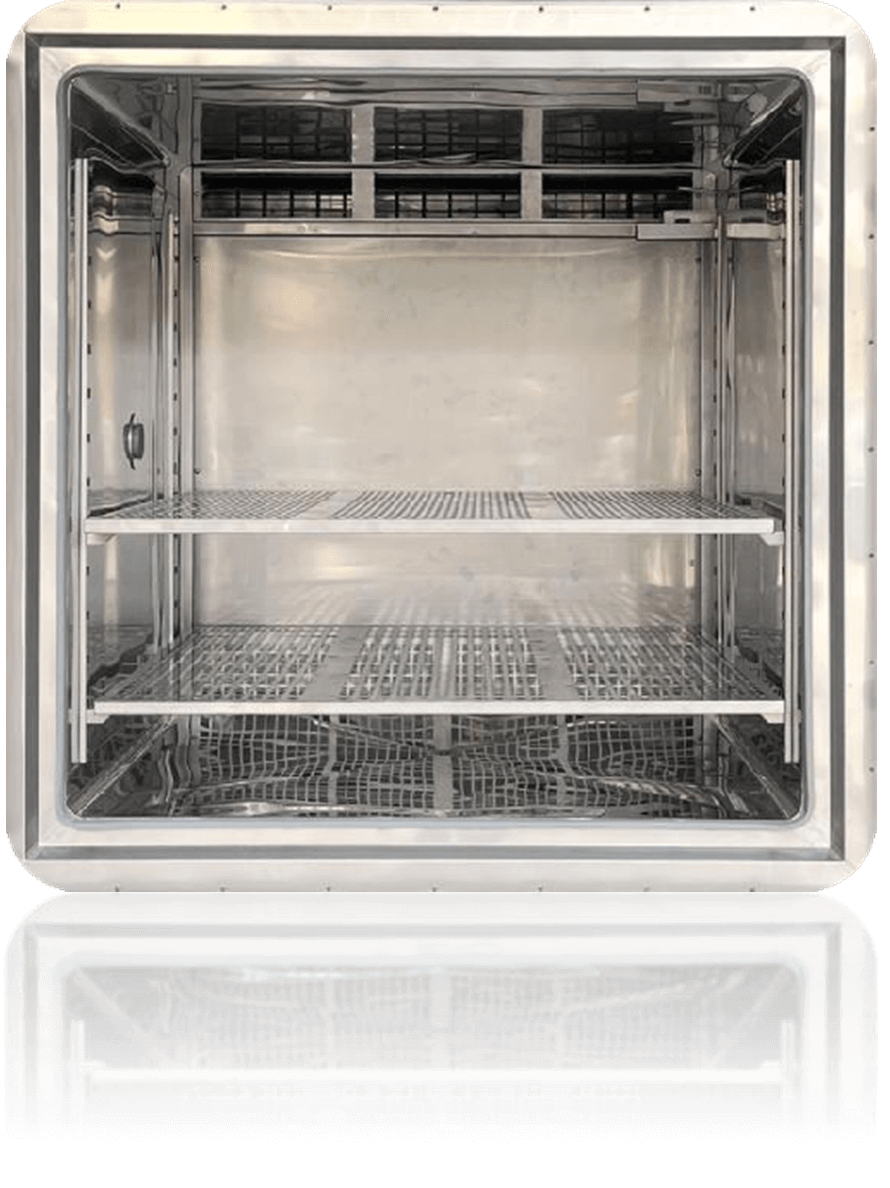

- Emergency servicesAdjustable, removable stainless-steel sample shelves for versatile testing.

- Built-in safety systems including over-temperature and over-current protection.

- CE certification and ISO17025 calibration for guaranteed performance accuracy.

- Ergonomic design with casters and cable ports for user convenience.

Model Overview – Temperature Cycle Test Chamber Series

As a leading temperature cycling test chamber manufacturer, we offer a variety of models to suit your specific temperature cycling test chamber cost requirements:

| Model | Internal Dimensions (mm) | Overall Dimensions (mm) | Temperature Range (°C) | Cooling Rate |

|---|---|---|---|---|

| T-50 | 320×350×450 | 930×1380×950 | -20°C ~ +150°C | 2°C/min |

| T-80 | 400×500×400 | 930×1450×950 | -20°C ~ +150°C | 2°C/min |

| T-100 | 400×500×500 | 860×1050×1620 | -20°C ~ +150°C / | 1°C/min |

| T-225 | 500×600×750 | 960×1150×1860 | -20°C ~ +150°C / -70°C ~ +150°C | 1°C/min |

| T-500 | 700×800×900 | 1180×1350×2010 | -40°C ~ +150°C | 1°C/min |

| T-1000 | 1000×1000×1000 | 1550×1550×2110 | -70°C ~ +150°C | 1°C/min |

| TK10-100 | 400×500×500 | 860×1050×1620 | -40°C ~ +150°C | 10°C/min (15°C/min optional) |

| TK10-220 | 500×600×750 | 960×1150×1860 | -70°C ~ +150°C | 10°C/min (15°C/min optional) |

Each model is built to suit specific industrial requirements, offering varying chamber volumes, temperature ranges, and ramp rates.

Applications of Temperature Cycling Test Chamber in the USA

The temperature cycling test chamber is a standard testing solution and essential environmental chamber for industries that depend on consistent product performance under thermal stress. Its wide range of applications includes:

- Automotive Components: Evaluating reliability of sensors, seals, gaskets, and electronic modules.

- Aerospace and Defense: Testing flight control systems, avionics, and composite materials for thermal fatigue.

- Electronics and Semiconductors: Ensuring printed circuit boards (PCBs) and chips endure temperature fluctuations.

- Battery and Energy Sector: Assessing lithium-ion batteries and storage devices for safety and stability.

- Construction Materials: Verifying coatings, adhesives, and sealants for expansion and contraction behavior.

- Research and Calibration Labs: Performing controlled tests for new material development and certification.

Accessories and Optional Components

To enhance your temperature cycle test chamber, we offer several optional components:

- Refrigerants: R404A and R23 (DuPont brand, environment-friendly and high-efficiency).

- Refrigerant Charging Kit: With pressure gauge and reusable hose.

- Nichrome Temperature Heater: For fast and uniform heating (2000W+).

- Capacitive Temperature Sensor: (Vaisala HMA6070) with ±0.01°C accuracy.

- Silicone Screw Plug: For cable hole sealing.

- Multi-tier Stainless-Steel Sample Holders: For large test volumes.

- High-efficiency Air Circulation Fan: For consistent temperature distribution.

How to Select the Best Temperature Cycling Test Chamber

When choosing a temperature cycling test chamber manufacturer, consider the following factors to ensure optimal return on investment:

- Temperature Range: Select based on your material or component’s thermal limits.

- Rate of Temperature Change: Faster rates save testing time for thermal fatigue evaluation.

- Size and Capacity: Choose a chamber size that matches your test load requirements.

- Controller Features: Look for programmable controllers with data logging capabilities.

- Safety Systems: Ensure built-in over-temperature, over-current, and phase protection.

- Certifications: Always opt for CE-marked and ISO17025-calibrated equipment.

- After-Sales Support: Choose brands offering full installation, training, and technical service.

Advantages of Choosing Testron’s Temperature Cycling Test Chamber in the USA

Testron Group has become a preferred temperature cycling test chamber supplier for industries across the USA due to its commitment to reliability, customization, and global service support. Our thermal cycling test chambers are designed for long-term stability, ensuring consistent results across thousands of test cycles.

Benefits include:

- Fast temperature recovery and exceptional accuracy.

- Energy-efficient design reduces operational costs.

- Compatibility with various global testing protocols

- Smart controller interface simplifies test scheduling.

- Low maintenance and easy service accessibility.

- Proven performance in leading U.S. testing laboratories.

- Affordable temperature cycling test chamber cost compared to competitors without compromising quality.

Why Testron Group Is a Trusted

Temperature Cycling Test Chamber Manufacturer

FAQs on Rain Test Chambers in the USA

What is a temperature cycling test chamber used for?

It is used to test how materials and components respond to alternating high and low temperatures, revealing potential mechanical or electronic failures.

How does a thermal cycling test chamber work?

It alternates between heating and cooling phases at controlled rates to simulate environmental stress conditions, replicating years of wear within days.

What is the typical temperature cycling test chamber price in the USA?

Prices vary based on chamber size, performance specifications, and customization. Contact Testron Group for the best quote tailored to your testing needs.

What industries use temperature cycling test chambers?

They are widely used in automotive, aerospace, electronics, defense, and research sectors to assess product reliability and performance.

What factors affect temperature cycling test chamber cost?

Factors include size, ramp rate capability, control precision, and additional features like data logging or liquid nitrogen cooling.

Why choose Testron as your temperature cycling test chamber supplier?

Testron combines world-class design, U.S.-based service support, ISO calibration, and competitive pricing, making it the best temperature cycling test chamber supplier for demanding industries.